Increase the rotational speed to the maximum.

If burrs still remain, then decrease the feed rate.

For horizontal burrs, up cut is recommended so that the brush tip pushes up the burrs.

To make sharp edge, increase the feed rate in 1000mm/min increments within the range where burrs can be removed.

Increasing the feed rate also helps to reduce the cycle time.

Decrease the rotational speed in 10 to 20% increments within the range where burrs can be removed.

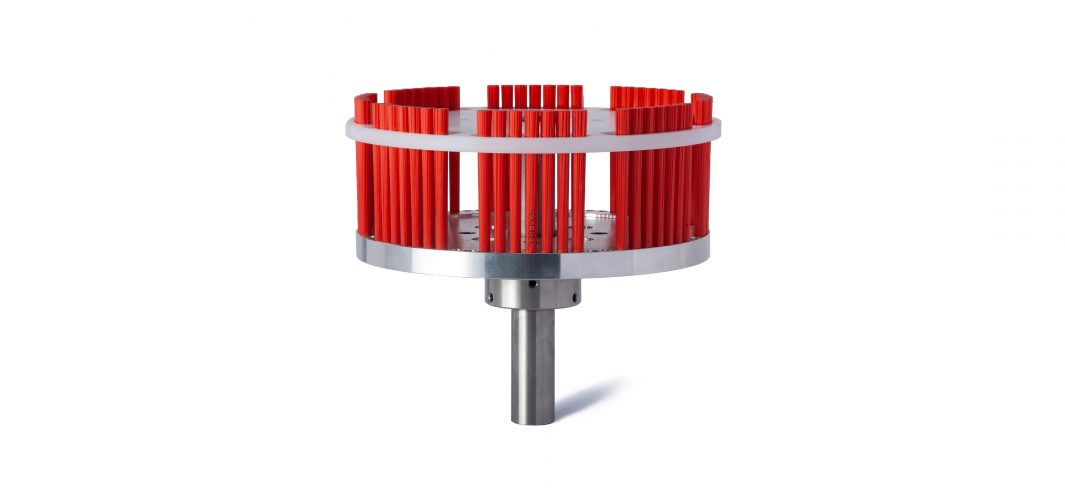

The grinding power of the Brush : Blue > White > Red

Select Brush color based on the workpiece material and burr root thickness.

Increase the feed rate in 1,000mm/min increments within the range where burrs can be removed.

Decrease the rotational speed in 10 to 20% increments within the range where burrs can be removed.

Check the Brush color.

Change the Brush with higher edge quality.

Edge quality of the Brush: Red > White > Blue

Make sure to select appropriate Brush color based on the workpiece material and burr root thickness.

Make sure to select appropriate Brush color.

Edge quality of the Brush : Red > White > Blue

The tool can be used for both dry and wet (oil-based and water-soluble) machining.

Wet machining may improve surface roughness and tool life.

When comparing in the same cycle time, increasing the number of passes makes bigger difference than decreasing feed rate.

Ideal for deburring, cutter mark removal and surface polishing with a width of 100 mm or more

*Rotate the Brush in a counterclockwise direction for the return pass.