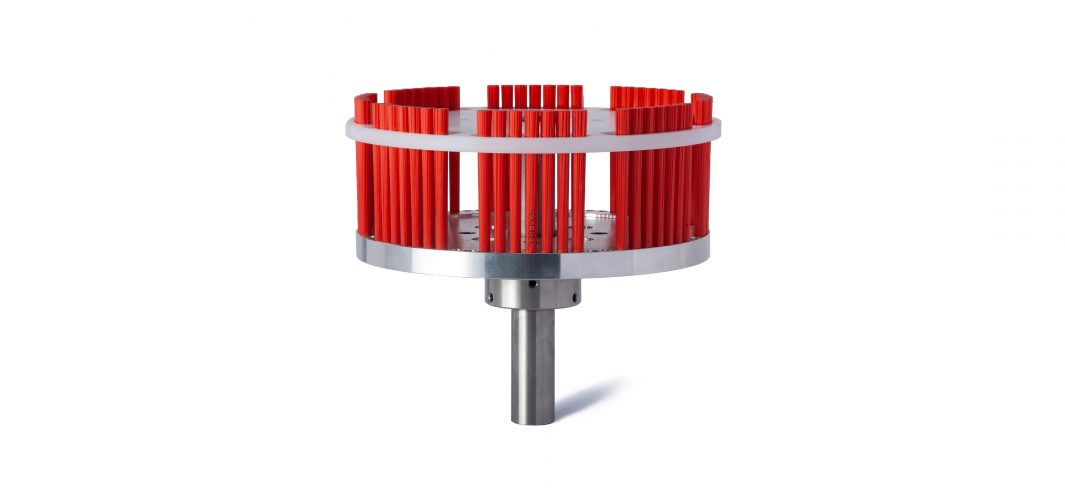

The usage and application are the same as those for the XEBEC Brush Surface, but components and assembly are different. The XEBEC Brush Surface is composed of a Brush and a Sleeve, while the XEBEC Brush Surface Extra-Large is composed of a Brush and a slide ring.

The slide ring prevents the Brush to spread wide in the the same way as the Sleeve does with XEBEC Brush Surface.

No. The ceramic fiber filament works as abrasive material.

The Brush utilizes ceramic fiber filament as the abrasive material. Unlike wire and nylon brushes, it does not deform. Since it retains its original shape, XEBEC Brush is an optimal tool for CNC deburring and polishing.

Ceramic fiber filaments that maintain an overwhelming grinding power at the tip are woven to form the bristle of the Brush. The Brush length shortens as it wears, but the ceramic fiber filaments self-sharpen. Theoretically, the grinding power of the ceramic fiber filament does not change up to the base of the Brush, but as the bristle becomes shorter due to wear, the bristle becomes stiffer and conversely, the grinding power increases. Therefore, we recommend using up to 2/3 of the total length of the Brush under the same processing parameters. If the Brush shortens further, it may be necessary to adjust the processing parameters to reduce the grinding power in order to continue deburring under the same condition. Some customers reuse Brushes for different surfaces or workpiece after using up 2/3 of their total lengths.

No. XEBEC Brushes do not contain abrasive grains that cause it. However, if dust and sludge accumulate, the performance of this product may be affected. It is recommended to wash them off.

XEBEC Brush is capable of removing burrs with root thickness of 0.2mm or burrs that can be easily removed with fingernails.

Burrs that are easily removable with fingernails.

It is applicable to any material with hardness of up to HRC65, including aluminum, steel, and cast iron, as well as difficult-to-machine materials such as stainless steel and Inconel.

Yes, it can. However, depending on the material, it may cause the workpiece to deform or to discolor. If deformation or discoloration becomes a problem, it may be possible to improve it by setting the rotational speed to about 1/10 of the recommended initial condition.

It can withstand temperatures up to 150 degree Celsius. The binder of the Brush is made of resin, and it cannot withstand higher temperatures.

If the tool cannot be rotated, the grinding power cannot be sufficient to remove burrs in most cases. We recommend using a lathe with a milling function.

Yes, we are able to offer drawings in PDF format. Please send us your request at: https://www.xebec-tech.com/en/contact/

*Please note that we are unable to offer drawings in any CAD data file such as dxf file.

Either is fine, although wet machining produces a better surface finish quality and helps to improve the tool life. This product can be used with both oil-based and water-soluble coolant.

Yes, it is possible to purchase just the Ring separately from other components.

We may be able to introduce you to a manufacturer. Please contact us at: https://www.xebec-tech.com/en/contact/

We do not make any machine tool, but we may be able to introduce you to a manufacturer. Please contact us at: https://www.xebec-tech.com/en/contact/

Wash the Brush lightly with water and then use an air blower to completely remove dust and coolant.

Diamond disc blade is recommended.