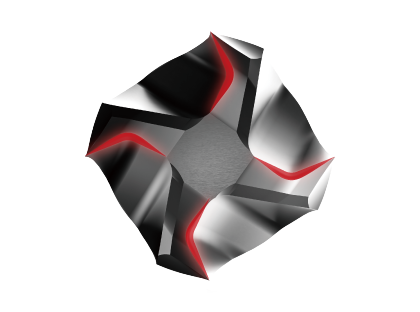

This tool provides an exact chamfer without secondary burrs, eliminating the time and cost of deburring.

This tool can be mounted on equipment shown below:

Machining center

Machining center Turn Mill Machine

Turn Mill Machine Lathe (no live tooling)

Lathe (no live tooling) Special machine

Special machine Robot

Robot Rotary tool

Rotary tool Rotary tool

Rotary tool

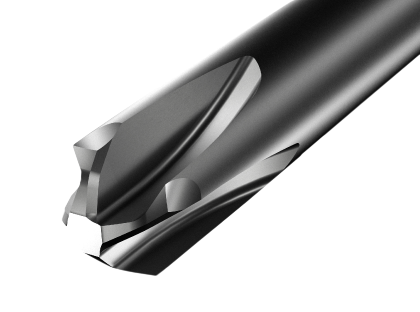

Unique design cuts a finished chamfer without secondary burrs. This eliminates the need for another deburring process.

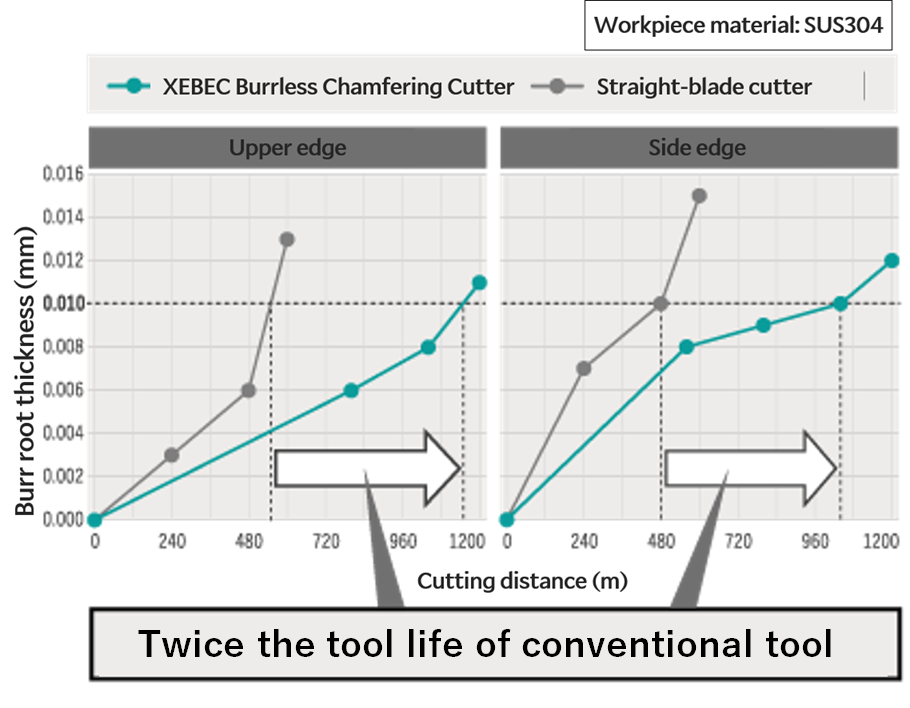

Tests have shown that the tool life of this cutter is at least twice as long as that of a conventional chamfering cutter.

Multi-blade design enables high feed rate. This reduces machining time for more efficient chamfering.

Ensures positional accuracy. The flat tip design prevents rounding and chipping that may cause tool length measurement errors.

Applicable materials: Steel P, stainless steel M, cast iron K, heat resistant alloy S, nonferrous metal N

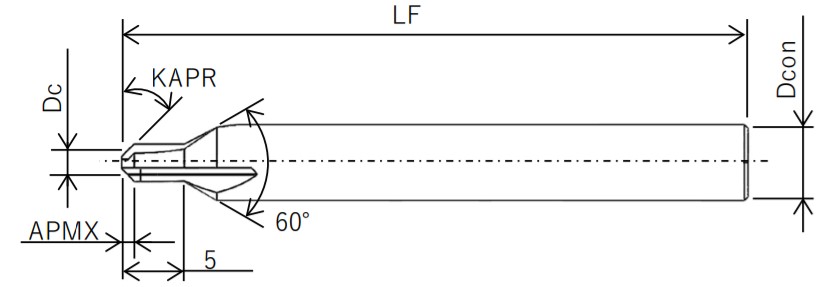

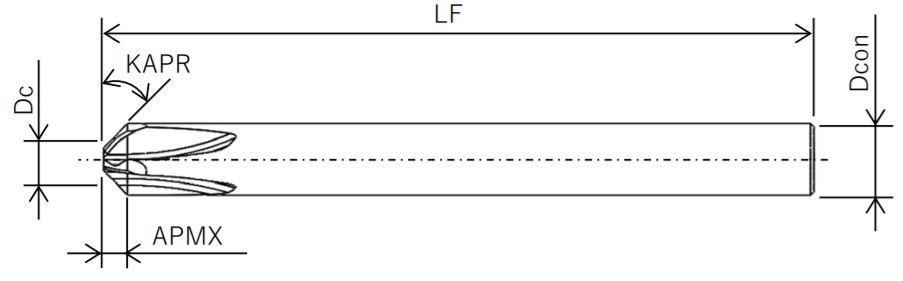

| Product code | Chamfering alignment diameter Dc (mm) |

Shank diameter Dcon (mm) |

Overall length LF (mm) |

Neck length L1 (mm) |

Maximum depth of cut APMX (mm) |

Cutting angle KAPR (deg.) |

Number of blades | Target chamfering size | Fig |

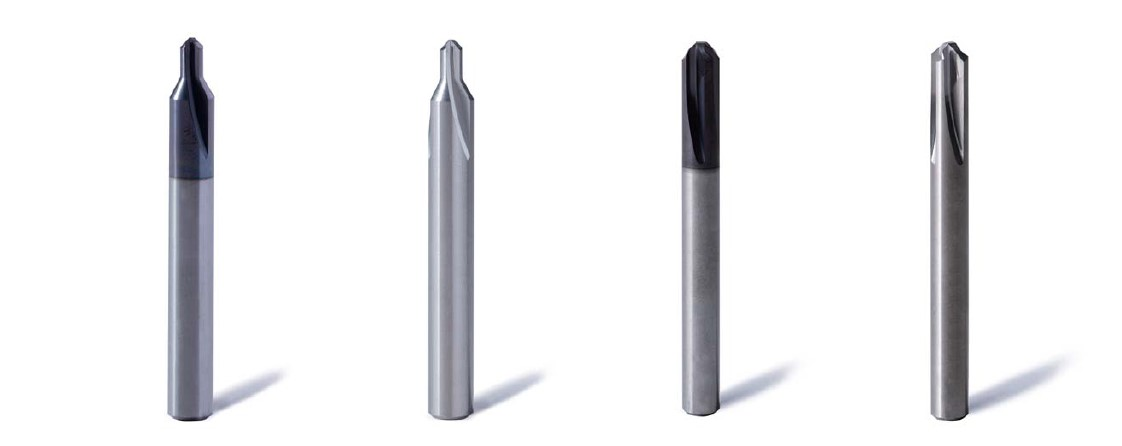

| XC-C-03-M | φ2 | φ6 | 50 | 5 | 1 | 45 | 3 | C0.3 – C0.6 | 18 |

| XC-C-06-M | φ4 | φ6 | 60 | – | 2 | 45 | 4 | C0.7 – C1.5 | 19 |

Applicable materials: Nonferrous metal N, Resin O

| Product code | Chamfering alignment diameter Dc (mm) |

Shank diameter Dcon (mm) |

Overall length LF (mm) |

Neck length L1 (mm) |

Maximum depth of cut APMX (mm) |

Cutting angle KAPR (deg.) |

Number of blades | Target chamfering size | Fig |

| XC-C-03-N | φ2 | φ6 | 50 | 5 | 1 | 45 | 3 | C0.3 – C0.6 | 18 |

| XC-C-06-N | φ4 | φ6 | 60 | – | 2 | 45 | 4 | C0.7 – C1.5 | 19 |