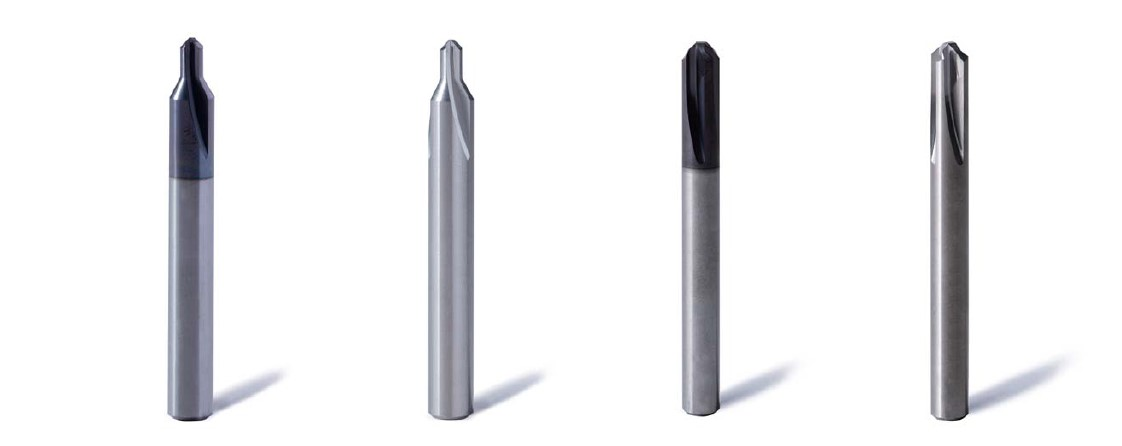

The XEBEC Burrless Chamfering Cutter is a chamfering tool with patented V-shaped blades that prevent burrs from forming. Since no deburring is required after chamfering, this cutter reduces time required for manual deburring, lowers tool costs, and shortens cycle times.

The cutting blades point inwards from the top and bottom edges of the chamfering range. This directs the plastic flow of the workpiece in toward the center of the chamfer area, where it is cut off as part of the cutting chip.

The chamfering alignment diameter is the width of the path drawn by the center point of the V-shaped blade as it rotates.

The chamfering alignment diameter is used to position the cutter at the center of the chamfer area. This prevents burrs from forming when chamfering.

It is made of micro-grain cemented carbide.

This cutter can used with a variety of materials, including resins, aluminum alloys, stainless steel, and steel alloys.

You can expect a higher burr-suppression effect when chamfering difficult-to-cut materials such as aluminum alloys and stainless steel.

The Burrless Chamfering Cutter is made of cemented carbide. Therefore, caution is required when working with materials close to the hardness of cemented carbide.

The tool life will probably be reduced when working workpieces with hardness of about HRC45.

This cutter has proven to work with materials such as MC nylon, Teflon, and CFRP.

Tool life will vary depending on the material, machining parameters, and burr size. In-house tests resulted in twice the tool life of conventional chamfering tools with straight blades.

We do not provide a resharpening service for this tool. However, some third parties may be able to resharpen the cutter if they have the appropriate equipment.

The dimensional tolerance on the shank (φ6.0) is h6 (-0.008~0).

The dimensional tolerance on blade tip angle is 45°±0.5°.

A:Yes, we can provide drawings as PDF or 3D solid models (STEP files).

Please send your request to: https://www.xebec-tech.com/en/contact/

Yes, it is possible to purchase just one.

The chamfer widths for which this cutter can be used are shown below. Please contact us if you wish to chamfer other sizes.

XC-C-03-x:C0.3 – 0.6

XC-C-06-x:C0.7 – 1.5

As the size of burr that is unacceptable and the area to be chamfered will differ from user to user, we recommend you set your own standard for replacing the tool.

This cutter requires the chamfering alignment diameter to be aligned with the center point of the V-shaped blade to prevent formation of burrs.

Using the tool vertically would mean the chamfering alignment diameter and chamfering center point would no longer be aligned. This would affect the ability of the tool to suppress burrs and probably result in secondary burring.

It is possible. However, as with cutting tools in general, tool life would be shortened by the higher cutting loads when the tool first cuts into the material.

It is possible. However, the chamfer area, which changes with the displacement of the workpiece, will need to be within the range of the cutting blades.

The chamfering alignment diameter (φ4) should also be within the chamfer area in order to suppress formation of burrs. Burrs may form if it is not.

Testing shows burrless chamfering is possible up to a feed rate of 0.09mm/t. However, higher feed rates increase the size of cutter marks (feed marks).

There is no need to use any specific coolant. You can use the same coolant as with other cutting tools such as drills and end mills.

Reduce the feed rate proportionally to adjust the feed per tooth speed appropriately.