The built-in spring helps to maintain stable load, which enables consistent performance, while reducing the need to adjust the Brush projection length frequently.

Machining center

Machining center Turn Mill Machine

Turn Mill Machine Lathe (no live tooling)

Lathe (no live tooling) Special machine

Special machine Robot

Robot Rotary tool

Rotary tool Rotary tool

Rotary tool| Product code | Target brush diameter (mm) |

Diameter for the sleeve shank (mm) |

Maximum rotational speed (min⁻¹) |

Accessories | Fig |

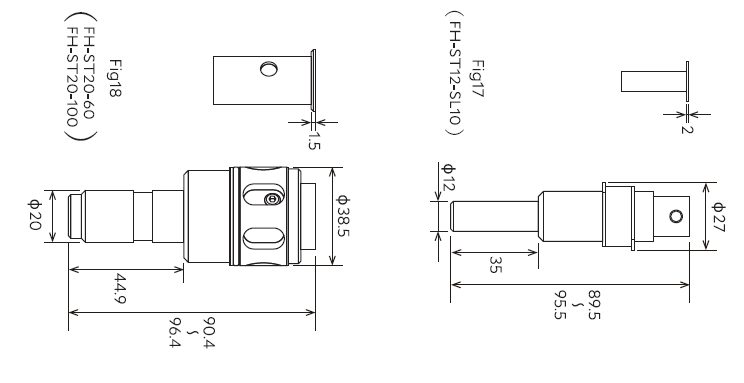

| FH-ST12-SL10 | φ6 | φ6 (with the supplied bush ①) | 10000 | ①φ6 Bush ②φ8 Bush ③Low-pressure spring ④Standard spring* ⑤High-pressure spring *Installed when shipped |

17 |

| φ15 | φ6 (with the supplied bush ①) | 6000 | |||

| φ25 | φ8 (with the supplied bush ②) | 5000 | |||

| φ40 | φ10 | 3000 | |||

| FH-ST20-60 | φ60 | φ12 | 2000 | φ12 bush | 18 |

| FH-ST20-100 | φ100 | φ16 | 1200 | φ16 bush | 18 |

| Spring type | Outer diameter (mm) |

Spring constant (N/mm) |

Overall length (mm) |

Load by stroke (N) | ||

| 0 mm | 6mm | |||||

| Standard spring | Installed | φ10 | 0.3 | 40 | 4.5 | 6.3 |

| Low-pressure spring | Attachment | φ10 | 0.3 | 30 | 1.5 | 3.3 |

| High-pressure spring | Attachment | φ10 | 0.55 | 38 | 7.7 | 11.0 |

| Maximum load spring | Sold separately | φ10 | 3.03 | 30 | 15.2 | 33.4 |

○ Apply the tool vertically when making it engaged with workpiece.

○ It can not be used if there are intermittent machining areas or protrusions.

○ In the case of horizontal machining center, telescopic function may not work if spring load is low.