This tool can be used with a machine capable of precise control of the angular position of the Sleeve.

It is possible to adjust the Brush projection length in increments of 0.05mm. In one single pass, it is possible to make an adjustment of up to 1mm.

This allows adjustments be made at a predetermined interval corresponding to the tool wear.

1. Figure out the amount of brush wear by process quantity or travel length.

2. Set and execute the macro program so that the projection amount is adjusted at the predetermined interevals.

Example:

Deburring an aluminium part

Travel length: 200mm per workpiece

【Condition】

1. Brush wear: 2μm per workpiece

2. Brush wear: 0.2mm per 100 workpieces (Total travel length 20,000mm)

【Adjustment cycle】

Set the cycle to every 100 workpiece (0.2mm brush wear)

Example:

Finish processing of a cast-iron part’s edges

Travel length: 1,500mm per workpiece

【Condition】

Brush wear 50μm (0.05mm) per workpiece

【Adjustment cycle】

Set the cycle to every 1,500mm (50μm brush wear)

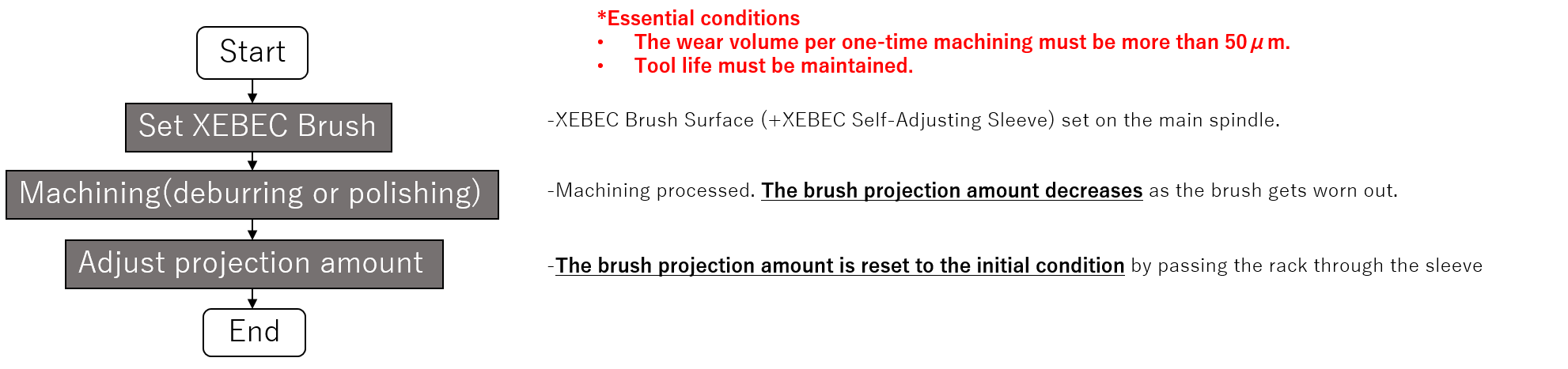

This is a method to adjust only the part that is worn out by one-time processing immediately after processing.

By passing the side gear of main body through the rack gear immediately after processing, the brush projection amount is reset to the initial condition.

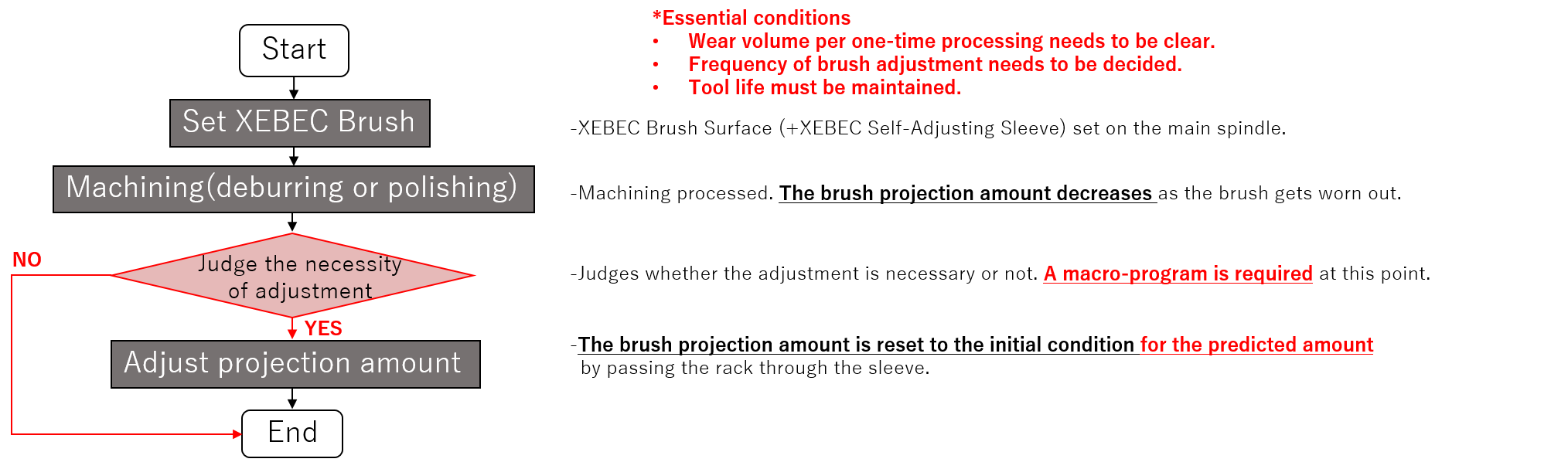

This is a method to adjust the cumulative wear volume generated by several processing at once.

By passing the side gear of main body through the rack gear once every several processing, the brush projection amount is reset to the initial condition.

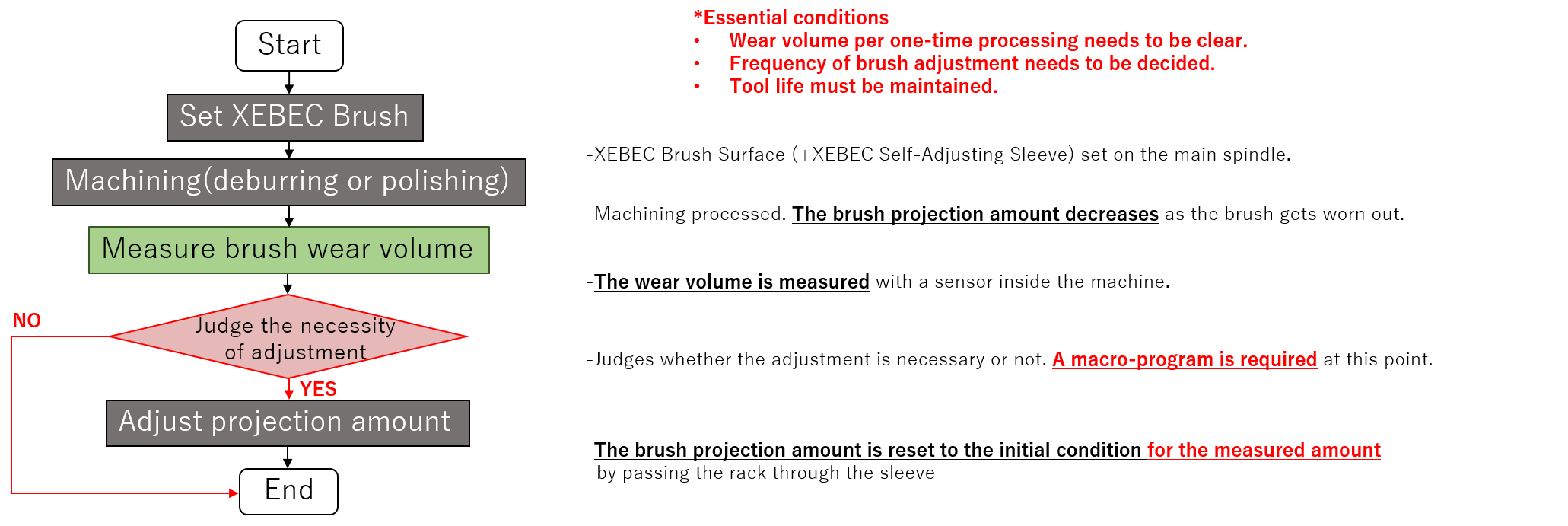

This is a method to measure the brush wear volume using the sensor inside the machine and adjust only when a certain amount is worn out.

After processing, the sensor inside the machine measures the brush wear volume and decides whether adjustment is necessary. If necessary, the brush projection amount is reset to the initial condition.

The concept and program are simple.

Just one counter is required (for tool life).

As the minimum adjustment amount is 50 μm, the wear volume per one-time processing must be more than 50 μm.

Cycle time gets longer due to every projection adjustment.

Recognition of the wear volume in advance is necessary.

(The wear volume of friction is a predicted value)

No minimum wear volume (wear volume: less than 50um/per time).

It might be possible to shorten the cycle time of pattern 1 (Every-time projection adjustment is not necessary).

A complicated macro program is required. (A program which decides whether adjustment is necessary or not).

At least two counters are necessary.(for tool life and for judging projection adjustment) .

Recognition of the wear volume in advance is necessary.

(The wear volume is a predicted value)

Accurate projection adjustment based on measurement is possible.

Only one counter is required (for tool life)

Recognition of the wear volume in advance is not necessary.

No minimum wear volume (wear volume: less than 50um/per time).

The sensor inside the machine is necessary.

Cycle time gets longer due to sensing.

Micro program for some points is necessary.

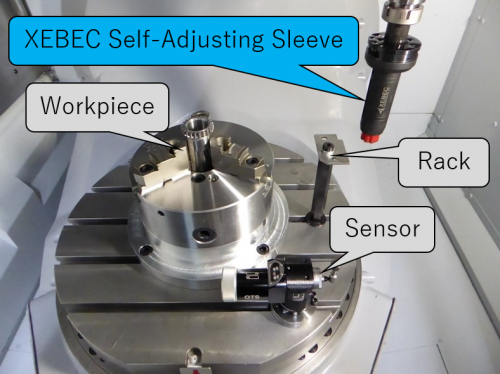

The following shows how three operating patterns will make an operation.

In the following, the target workpiece and the sensor inside the machine will appear in addition to the XEBEC Self-Adjusting Sleeve and the auxiliary item, the rack.

Please check the arrangement as shown below.

The video is the same one as pattern 1.

Automatically adjusts the Brush protrusion length with the built-in gear mechanism.

Helps prevent human errors and achieve consistent machining performance.