Many people think you need to chamfer edges when nylon and wire brushes cannot remove burrs sufficiently. However, XEBEC provides an alternative solution — Ceramic fiber brushes.

XEBEC brushes can remove burrs left behind by nylon and wire brushes because they use ceramic fiber as the abrasive material. They also contain a higher percentage of abrasive than nylon brushes. This enables them to deburr harder materials such as stainless steel and titanium.

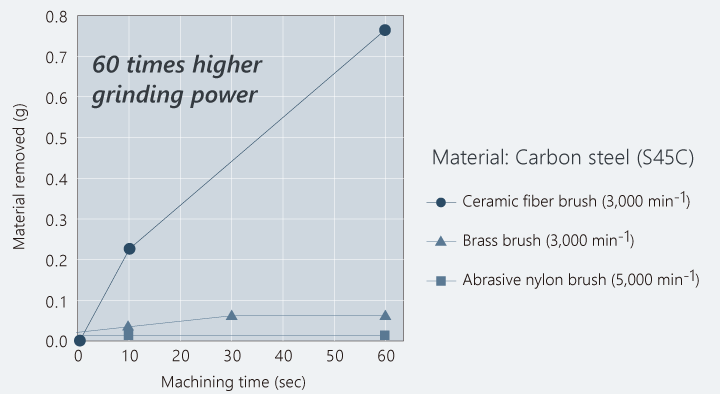

Graph1 illustrates the superior grinding power of XEBEC ceramic fiber brushes with respect to abrasive nylon brushes (60 times greater) and wire brushes (10 times greater).

Graph 1: Grinding power of ceramic fiber, wire, and abrasive nylon brushes

The ceramic fiber brush used in the original test above was A32-CB40M, which is a hard brush with a 40mm diameter. The abrasive nylon brush had a grit of 180.

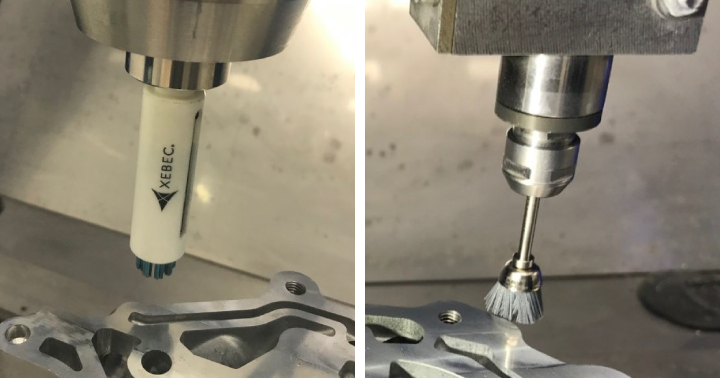

This is a simple test to demonstrate once again the difference in grinding performance between ceramic fiber and abrasive nylon brushes. You are welcome to try it yourself. The ceramic fiber brush used for the new test is A32-CB15M, which is the same hardness as the original brush, but with a smaller (15mm) diameter. The abrasive nylon brush used is a 13mm diameter cup-type.

Image 1: XEBEC ceramic fiber brush (left) and abrasive nylon brush (right)

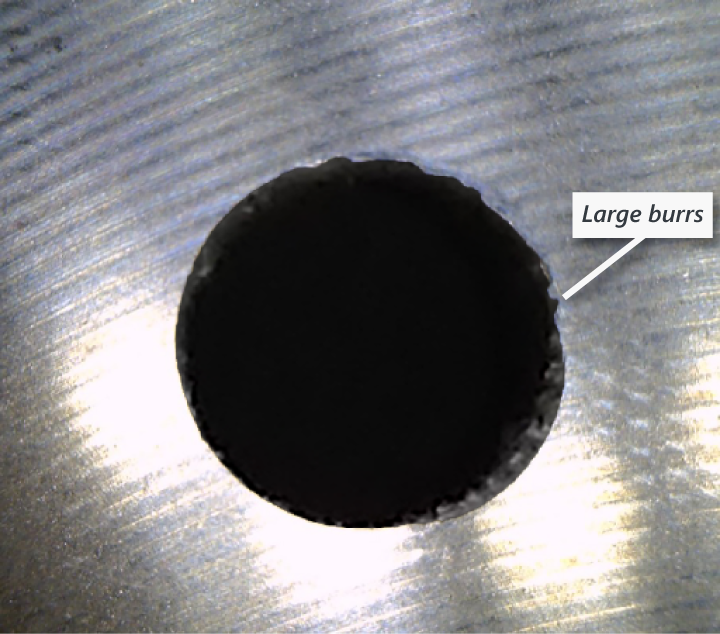

The surface of the workpiece exhibits the characteristic cutter marks of a face milling tool. Burrs are also evident on the various edges of the workpiece as shown in Image 2.

Image 2: Cutter marks and burrs visible on the workpiece

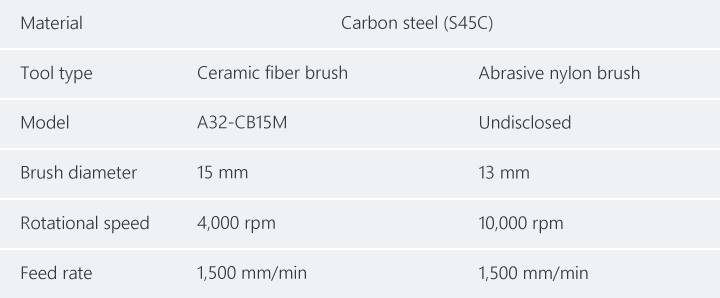

The machining parameters used in this test are shown in Chart 1.

Chart 1: Machining parameters used in this test

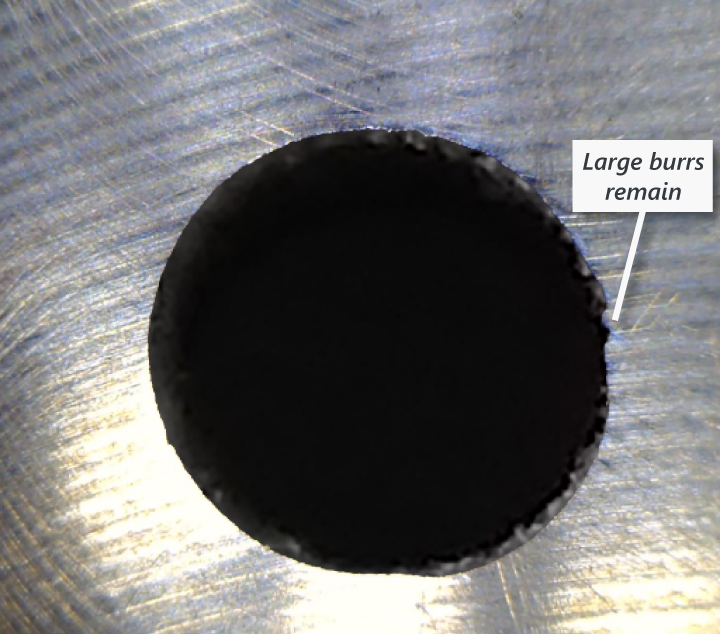

The finish from machining with the abrasive nylon brush is shown in Image 3. While difficult to see in this image, the minute burrs have been removed. However, the large burrs on the right side of the image have not been removed. The large burrs left by the face milling tool remain angled into the hole. The flexible bristles of the nylon brush are not capable of removing these burrs.

Image 3: Finish by abrasive nylon brush

The finish from machining with the XEBEC ceramic fiber brush is shown in Image 4. The edge appears to be overly rounded. However, this can be improved by reducing rotational speed and increasing feed rate. Note that the cutter marks have been removed.

Image 4: Finish by ceramic fiber brush

This test demonstrates the high grinding power of XEBEC’s ceramic fiber brushes. In addition to deburring, XEBEC ceramic fiber brushes are frequently used to improve surface roughness, remove cutter marks, and disguise marks from mismatched machining.

Please contact XEBEC Technology or your nearest distributor if you are interested in removing large burrs from machined edges. We provide brushes on loan for testing.

XEBEC Technology has been helping factories and machining shops around the world automate their deburring processes since 2002. With our wealth of knowledge accumulated over the years, we strive to solve customer deburring problems faster than before. We aim to change the way people think about deburring and create value-added in customer finishing processes.