Tokyo, Japan — August 21, 2023 — XEBEC Technology Co., Ltd. (President & CEO: Norihiko Sumiyoshi) will display its new Burrless Chamfering Cutter at EMO Hannover 2023 as a key part of the global release of this product.

XEBEC Technology, a Japanese manufacturer of high-quality deburring tools, has developed a unique chamfering tool with patented V-shaped blades that eliminates the need to remove secondary burrs after chamfering. The new tool is the XEBEC Burrless Chamfering Cutter(TM). It can be used on machining centers and CNC lathes equipped with live tooling.

Image 1: The XEBEC Burrless Chamfering Cutter

XEBEC develops tools that enable deburring to be completed on the same machining center immediately after milling and drilling. XEBEC’s market research revealed that over 80 percent of its customers were removing secondary burrs after chamfering.

Deburring is one of the final steps in machining parts. Despite increasing automation in recent years, deburring is still an area for concern for production and operation engineers, particularly those responsible for mass production. The cost of finishing edges twice in mass production is significant. If 5 seconds is required for a deburring process after chamfering, then an additional 277 hours would be required for monthly production of 200,000 units.

The size and shape of burrs formed during machining may be affected by slight changes in material composition and tool wear. Therefore, the optimal parameters for deburring one day may not work the same the next.

One common way to finish edges and remove burrs is chamfering with straight edge cutting tools. However, this results in small secondary burrs forming on the top and bottom edges as material pushed ahead of the blade flows off to the sides. The mechanism resembles the way a snowplow clears snow from a road.

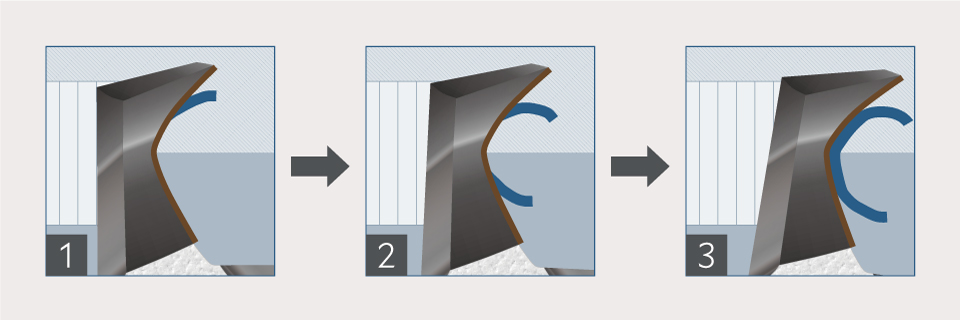

The XEBEC Burrless Chamfering Cutter works as follows:

The first blade cuts the top edge of the material pushing it down toward the tool path. A second blade then cuts the bottom edge of the material pushing it up toward the tool path. Finally, a third blade cuts the material still attached in the center of the tool path and the chip is discarded.

Image 2: Burr prevention mechanism — First blade cuts top edge, second blade cuts bottom edge, and third blade breaks the chip in the center.

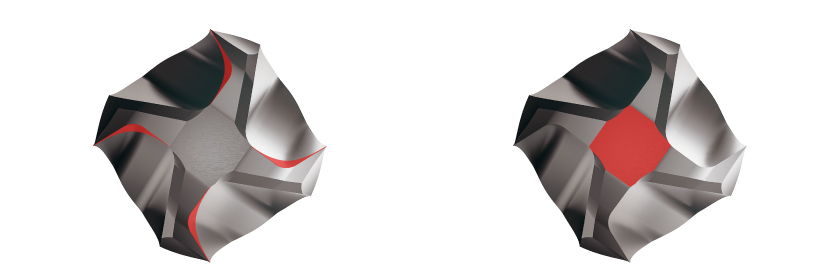

The XEBEC Burrless Chamfering Cutter eliminates burrs on chamfered edges. Positioning accuracy is also improved by a flat tip resistant to rounding and chipping that would result in tool length measurement errors. The multi-blade design enables high feed rates for reduced machining time and provides twice the tool life of conventional straight edge blades.

Image 3: Benefits of XEBEC Burrless Chamfering Cutter — (left) Multiple V-shaped blades reduce machining time and (right) flat tip for accurate tool length measurement.

The XEBEC Burrless Chamfering Cutter is available in coated and uncoated versions as well as two shank types for different cutting diameters. The coated version is ideal for harder materials, including heat-resistant super alloys. The uncoated version has extremely sharp cutting edges making it ideal for softer materials such as non-ferrous metals, plastics, and composite materials. The stepped shank type has three cutting edges, and the straight shank type has four cutting edges. The tool can cut chamfers from C0.3 to C1.5.

| Product code | Shank dia. (mm) |

Length (mm) |

Depth of cut (max., mm) |

Chamfer angle | Blades | Chamfer size |

| XC-C-03-M | φ6 | 50 | 1 | 45 | 3 | C0.3 – C0.6 |

| XC-C-06-M | φ6 | 60 | 2 | 45 | 4 | C0.7 – C1.5 |

Specification Table: XEBEC Burrless Chamfering Cutter

XEBEC Technology is committed to solving the world’s deburring problems and continues to research the mechanism of burr formation and suppression. It has previously developed a cutter with a spherical head for deburring a wide variety of 3D contours such as crossholes.

XEBEC Technology is committed to solving the world’s deburring problems and continues to research the mechanism of burr formation and suppression. It has previously developed a cutter with a spherical head for deburring a wide variety of 3D contours such as crossholes.

XEBEC Technology will be at EMO Hannover 2023 in Hall 3, Stand I34.

XEBEC develops, manufactures, and sells industrial tools for deburring, polishing, chamfering, and surface finishing. XEBEC has been helping factories and machining shops around the world automate their deburring processes since 2002. With our wealth of knowledge accumulated over the years, we strive every day to solve customer deburring problems faster than before. We aim to change the way people think about deburring and create value-added in customer finishing processes.

For more information, please visit https://www.xebec-tech.com/en/

Media Contact

Email: customerservice@xebec-tech.co.jp

Tel. +81-3-3239-3481