Tokyo, Japan — September 19, 2025 — XEBEC Technology Co., Ltd. (President & CEO: Norihiko Sumiyoshi) will display a unique solution for automated deburring on CNC lathes at EMO Hannover 2025.

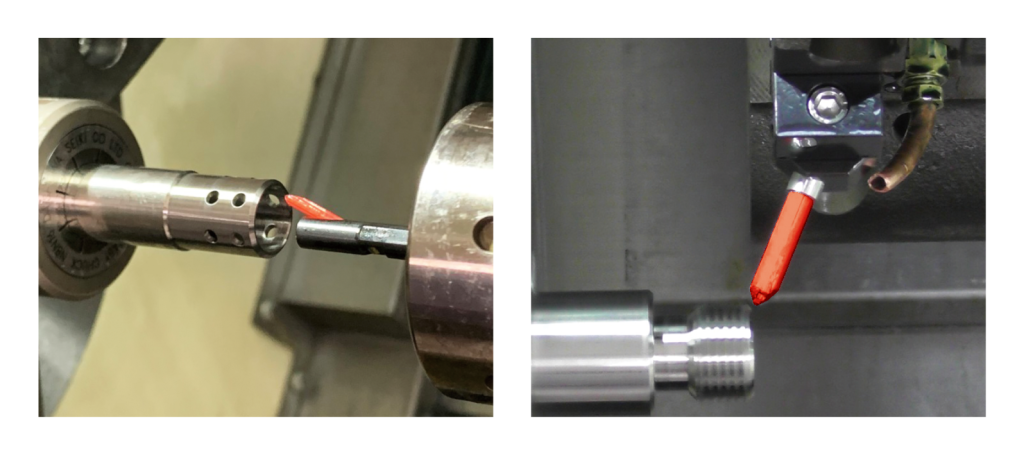

Image 1: XEBEC Brush Turning (shanks and replaceable brushes)

XEBEC Brush™ Turning is the first practical application of ceramic fiber brush technology for deburring on CNC lathes. It does not require live tooling and is mounted on the turret alongside other turning tools. Removing burrs on the same machine as facing and turning operations realizes important time and cost savings. It also eliminates the variable quality and danger inherent to manual deburring, particularly when the operator must reach into a moving machine to deburr by hand.

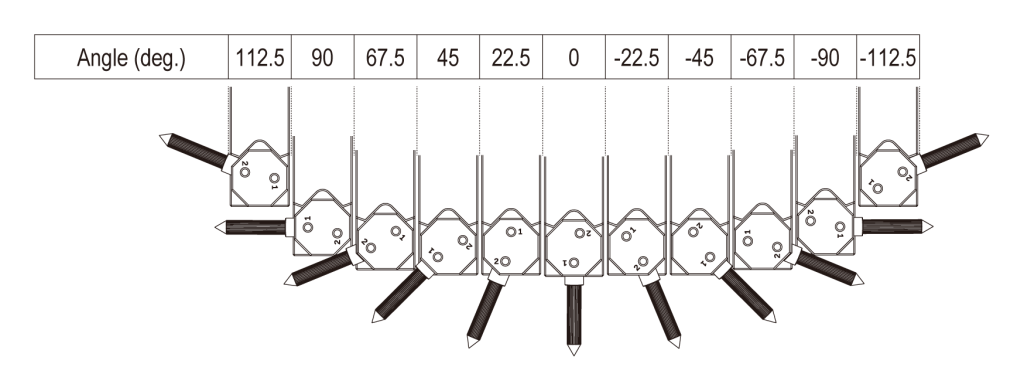

XEBEC Brush Turning is ideal for removing fine burrs no thicker than 0.1 mm. The tool is pulled in the x-axis away from the main spindle when facing and pulled in the z-axis away from the main spindle when ID or OD deburring. Brushes are available in three bristle variants (A11 Red, A21 White, and A32 Blue) with varying stiffness and two sizes (φ2.5 mm and φ6 mm). The tool consists of a reusable shank and a brush, which must be replaced when the usable bristle length is reached. Typical applications are deburring of crossholes and threads.

Image 2: Crosshole deburring (left) and thread deburring (right)

Image 2: Crosshole deburring (left) and thread deburring (right)

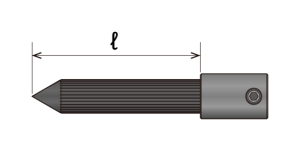

The square shank type can be set to eleven different brush angles, as needed to avoid tool collision.

Image 3: Brush angles of square shank type

Image 3: Brush angles of square shank type

The round shank version is 11 mm high, enabling 12 mm bores and ID threads to be deburred. The brush angle of the round shank type is fixed at 20 degrees. This shallow angle (close to horizontal) allows the brush’s flexible fibers to deburr discontinuous surfaces such as crossholes. The small brush (φ2.5 mm) can negotiate crossholes up to 3 mm in diameter. The large brush (φ6 mm) can be used to deburr any size crosshole.

For more information, please visit https://www.xebec-tech.com/en/products/tm/

XEBEC Technology will exhibit this tool at EMO Hannover 2025 in Hall 3, Stand E25 from September 22 to 26.

Table1 : Brushes

|

Brush (color) |

Product code |

Brush dia. (mm) |

Brush length ℓ (mm) |

Matching shank |

|

A11(red) |

A11-TB025 |

φ2.5 |

15 |

TM-SH-06 |

|

A11-TB06 |

φ6 |

30 |

TM-SH-S2020 |

|

|

TM-SH-S2525 |

||||

|

TM-SH-12 |

||||

|

A21 (white) |

A21-TB06 |

φ6 |

30 |

TM-SH-S2020 |

|

TM-SH-S2525 |

||||

|

TM-SH-12 |

||||

|

A32 (blue) |

A32-TB06 |

φ6 |

30 |

TM-SH-S2020 |

|

TM-SH-S2525 |

||||

|

TM-SH-12 |

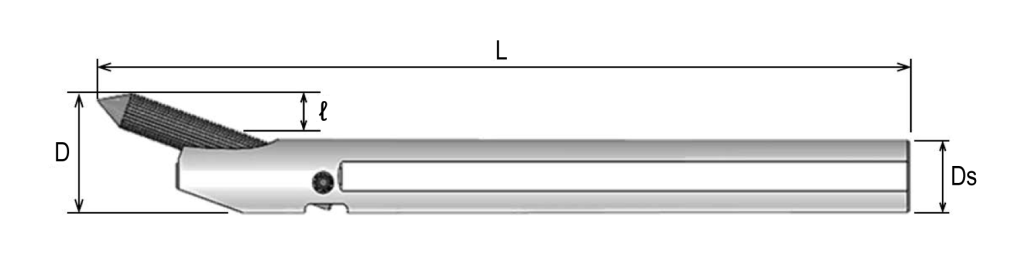

Image4 : Brush diagram

Table 2: Round shanks

|

Product code |

Length |

Shank dia. |

Usable bristle length |

Bore size |

Cutting dia. |

Max. |

Matching |

|

TM-SH-06 |

107 |

φ6 |

3.0 |

≥ 11 |

≥φ12 |

<φ3 |

A11-TB025 |

|

TM-SH-12 |

133 |

φ12 |

5.5 |

≥ 20 |

≥φ21 |

No limit |

A11-TB06 |

|

A21-TB06 |

|||||||

|

A32-TB06 |

Image 5: Round shank diagram

Table 3 : Square shanks

|

Product code |

Length |

Shank height |

Height |

Shank width |

Width |

Shank length |

Matching brush |

|

TM-SH-S2020 |

124 |

20 |

26 |

20 |

24 |

90 |

A11-TB06 |

|

A21-TB06 |

|||||||

|

A32-TB06 |

|||||||

|

TM-SH-S2525 |

133 |

25 |

31 |

25 |

24 |

100 |

A11-TB06 |

|

A21-TB06 |

|||||||

|

A32-TB06 |

Image 6 : Square shank diagram

XEBEC develops, manufactures, and distributes innovative tools for deburring, polishing, chamfering, and surface finishing. XEBEC has been helping factories and machining shops around the world automate their deburring processes since 2002. We aim to change the way people think about deburring and create value-added in customer finishing processes.

Shintaro Yoshihara, Manager, Global Marketing & Sales

Anton Peersman, Customer Care Manager, Global Marketing & Sales

Email: customerservice@xebec-tech.co.jp

Tel. +81-3-3239-3481

<ENDS>