XEBEC Brush speeds up time-consuming manual polishing work.

XEBEC Brush shortened polishing time from 60 min to 1.5 min.

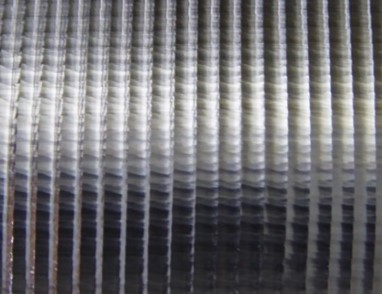

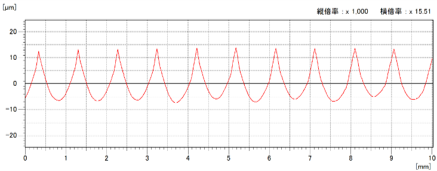

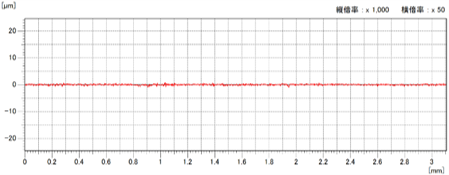

| Before | After |

| Rz = 6.1μm Ra = 1.4μm |

Rz = 0.337μm Ra = 0.029μm |

|

|

Material |

NAK55 |

Tools |

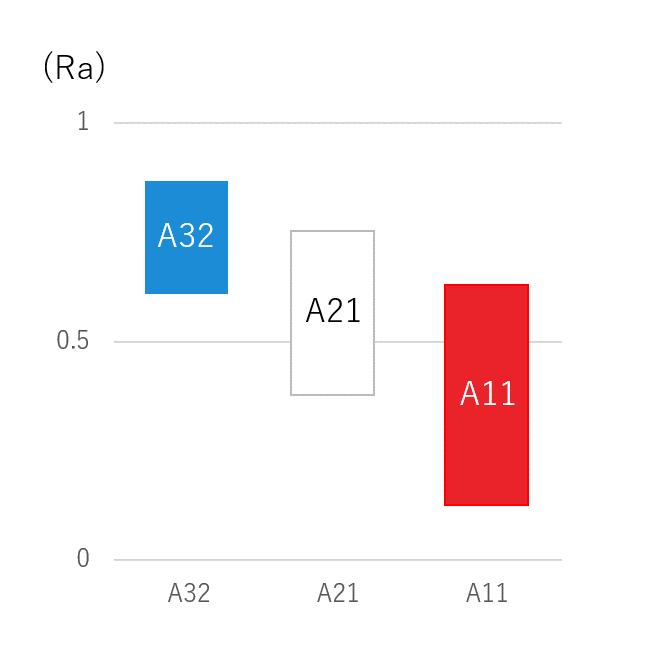

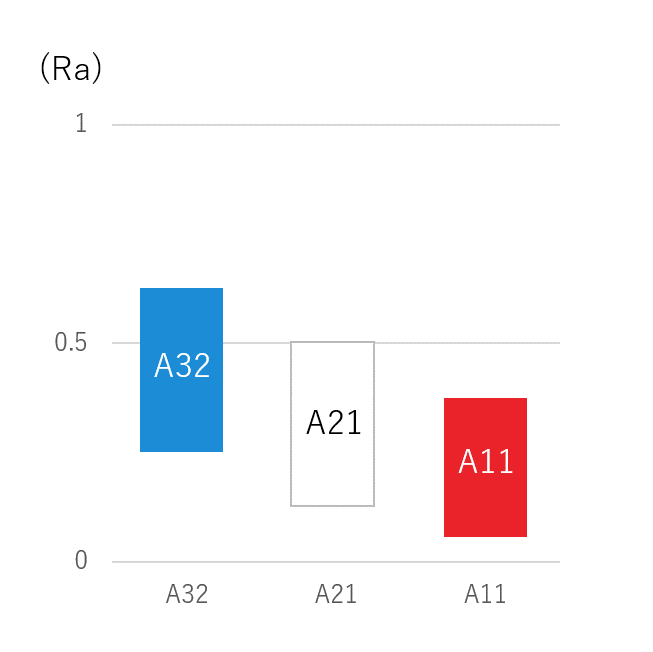

Rough finish (up to Ra 0.2μm): A32-CB25M

→Finishing: A11-CB25M |

Processing conditions |

Rough finishing: Rotational speed 5000min-1 Feed rate 500mm/min Depth of cut 0.3mm Finishing: Rotational speed 5000min-1 Feed rate 500mm/min Depth of cut 0.2mm |

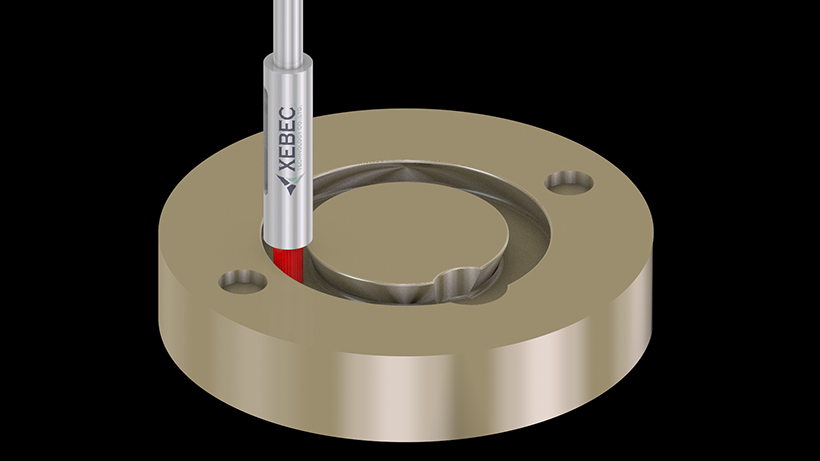

・Tool mark removal

・Removal of cusps, rough and medium polishing

・Eliminating labor work

・Consistent quality

・Time saving

・High skills and experiences are not required

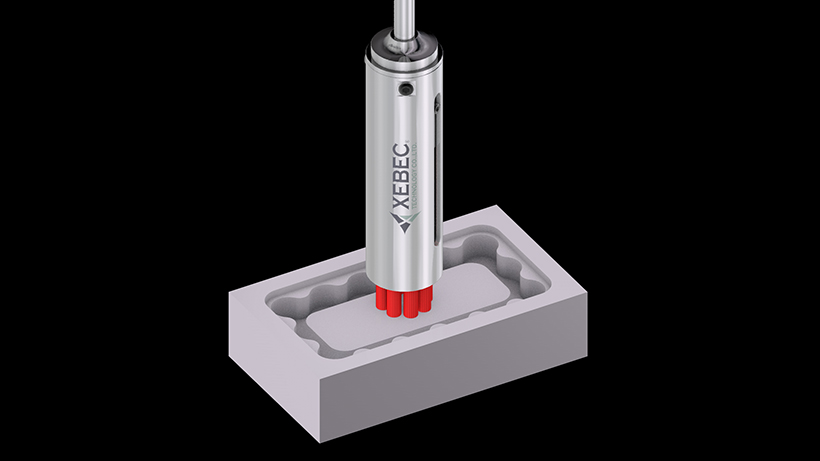

XEBEC Brush is made of the highly abrasive ceramic fiber, which was specifically developed for CNC machine deburring and polishing.

XEBEC Brush enables CNC machine deburring and polishing thanks to its advantages: overwhelming grinding power, consistent cutting performance and no deformation even after repeated uses.

|

|

|

|

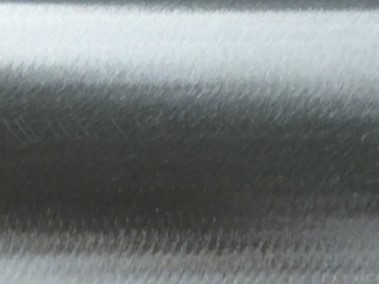

| Before | After |

|

|

|

|

| Surface roughness: Ra4.912μm Rz21.81μm | Surface roughness: Ra0.159μm Rz1.557μm |

Workpiece Information |

Turbine blades |

Pre-processing |

Ball end milling |

Polishing time |

3 minutes 20 seconds |

Polishing area |

W 60 x L 125 mm |

| Artificial bones | Dovetail groove | Vacuum forming moulds |

|

|

|

The achievable surface roughness is different depending on the Brush color. Please see the chart below to select a suitable Brush color.

| Non-Ferrous | Ferrous |

|

|