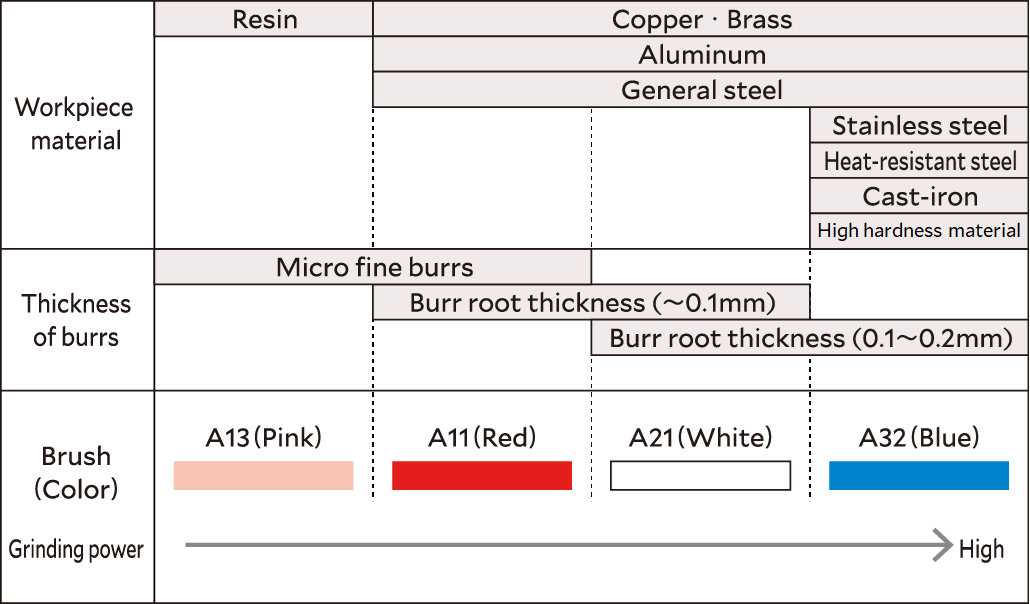

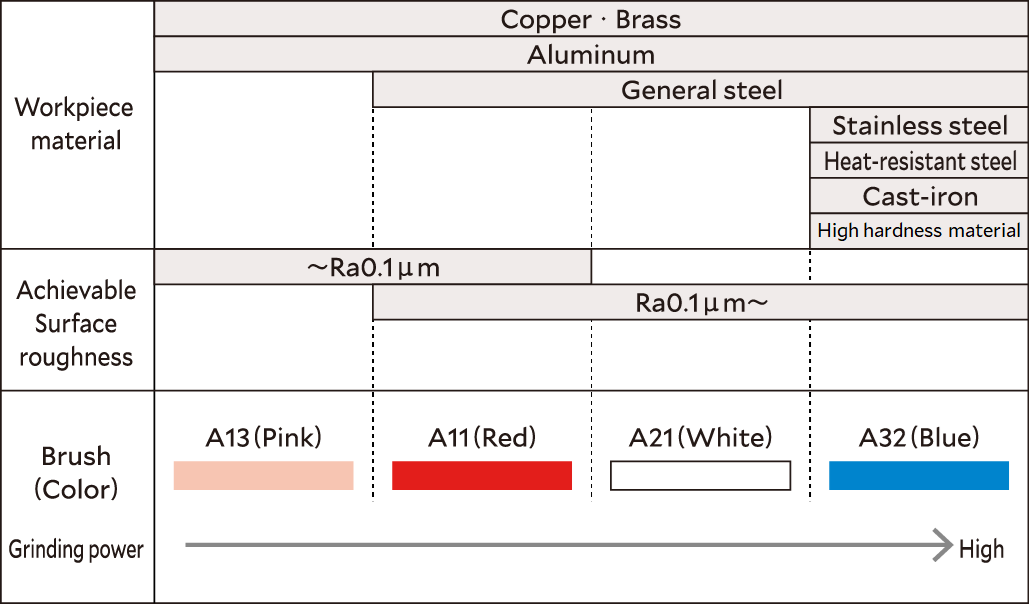

Grinding power differs depending on Brush color.

Refer to the chart below and select the brush color based on the workpiece material and burr root thickness.

>Click here to see lineup

Select the brush size based on workpiece size and shape, interfering objects such as jigs, attachable tool length and cycle time.

It is recommended to use the brush size which is 1.5 to 2 times wider than the width of the surface of the workpiece.

Please watch the video below to see what is the difference of processing paths by brush size.

>Click here to see lineup

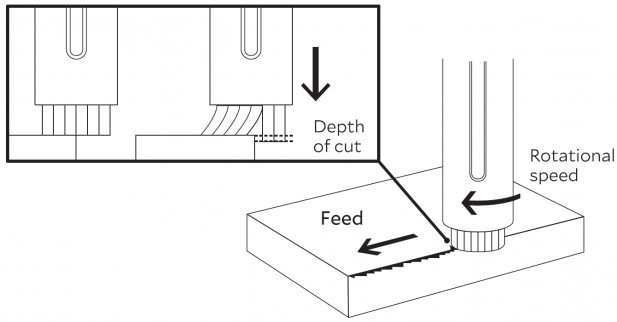

Set the machining parameters depending on the purposes, deburring or cutter mark removal and polishing.

The main parameters are:

1. Rotational speed 2. Depth of cut 3. Feed rate

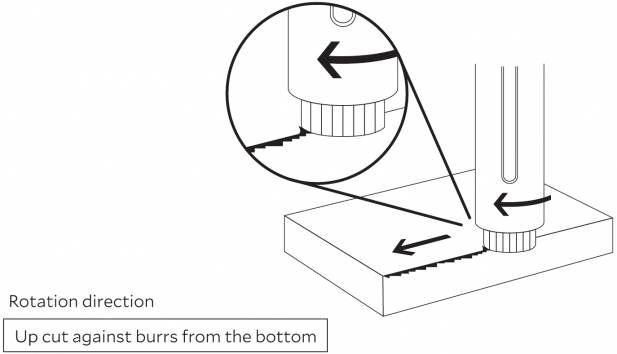

Rotational direction of the Brush has a significant impact on the deburring capability.

For burrs in horizontal direction (i.e. side burr) generated after milling, machining must be done by up cut whereby the brush pushes upward against the burrs from the bottom.

When down cutting, there is a possibility that the burrs may not be removed properly because the burrs may get bent and stuck to the surface.

For vertical burrs (i.e. top burrs), there is no significant difference by rotational direction.

| Product code | Rotational speed (min⁻¹) | Depth of cut (mm) | Feed rate (mm/min) | Brush projection (mm) | |||||||

| Deburring | Cutter mark removal, polishing |

Maximum | Vertical burrs | Horizontal burrs | Cutter mark removal, Polishing |

Burr root thickness 0.05mm | Burr root thickness 0.1mm | Cutter mark removal, Polishing |

Deburring | Cutter mark removal, Polishing |

|

| A13-CB06M A11-CB06M A21-CB06M |

8000 | 10000 | 10000 | 0.5 | 0.5 | 0.3 | 4000 | 2500 | 300 | 10 | 10 |

| A32-CB06M | 8000 | 10000 | 10000 | 0.3 | 0.3 | 0.3 | 4000 | 2500 | 300 | 10 | 10 |

| A13-CB15M | 4800 | 6000 | 6000 | 1 | 1 | 0.5 | 4000 | 2500 | 300 | 10 | 10 |

| A11-CB15M A21-CB15M A32-CB15M |

4800 | 6000 | 6000 | 0.5 | 1 | 0.5 | 4000 | 2500 | 300 | 10 | 10 |

| A11-CB25M A21-CB25M A32-CB25M |

4000 | 5000 | 5000 | 0.5 | 1 | 0.5 | 4000 | 2500 | 300 | 15 | 10 |

| A11-CB40M A21-CB40M A32-CB40M |

2400 | 3000 | 3000 | 0.5 | 1 | 0.5 | 4000 | 2500 | 300 | 15 | 10 |

| A11-CB60M A21-CB60M A32-CB60M |

1600 | 2000 | 2000 | 0.5 | 1 | 0.5 | 4000 | 2500 | 300 | 15 | 10 |

| A11-CB100M A21-CB100M A32-CB100M |

960 | 1200 | 1200 | 0.5 | 1 | 0.5 | 4000 | 2500 | 300 | 15 | 10 |

The tool can be used for both dry and wet (oil-based and water-soluble) machining.

Therefore, you can use the coolant which you are using in machining process.

Generally, wet machining are more effective to improve the surface finish quality and tool life.