This tool can be mounted on machining center (XYZ-axis) or combined lathe (XZY or XZC-axis). 3-axis simultaneous control is required.

*For combined lathe, polar coordinate interpolation is required.

*It cannot be used manually.

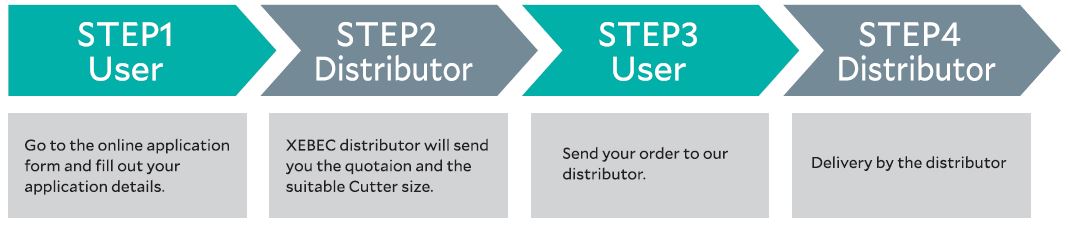

You can check whether XEBEC Back Burr Cutter & Deburring Tool Path is applicable for your hole-burr problem and environment.

The result will be available soon.

Please access from the following link.

Please send us a completed “XEBEC Back Burr Cutter & Deburring Tool Path application sheet” if you have difficulties filling out the online form. We will select an optimal Cutter size, assess whether XEBEC Back Burr Cutter & Deburring Tool Path is applicable to your workpiece and machining equipment, and provide XEBEC Tool Path Code.

There are 2 types of application sheet; for machining center and combined lathe.

Please download and fill out a sheet depending on your machining equipment.

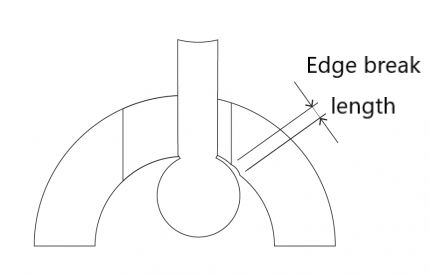

For the reason above, we consider “a width of an edge after deburring” as “edge break length”

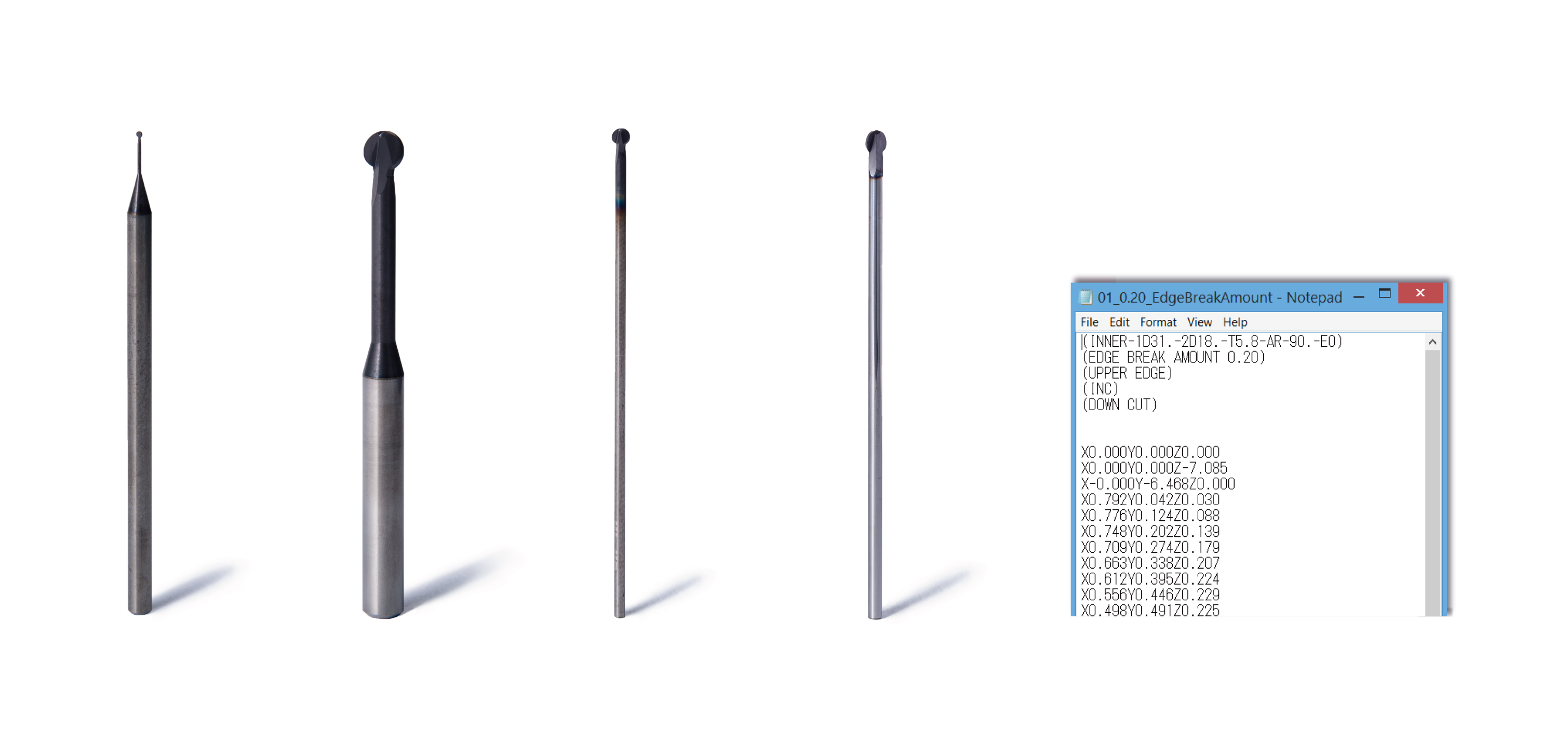

As a result of having pursued the effective shape for crosshole deburring, the Cutter is spherical.

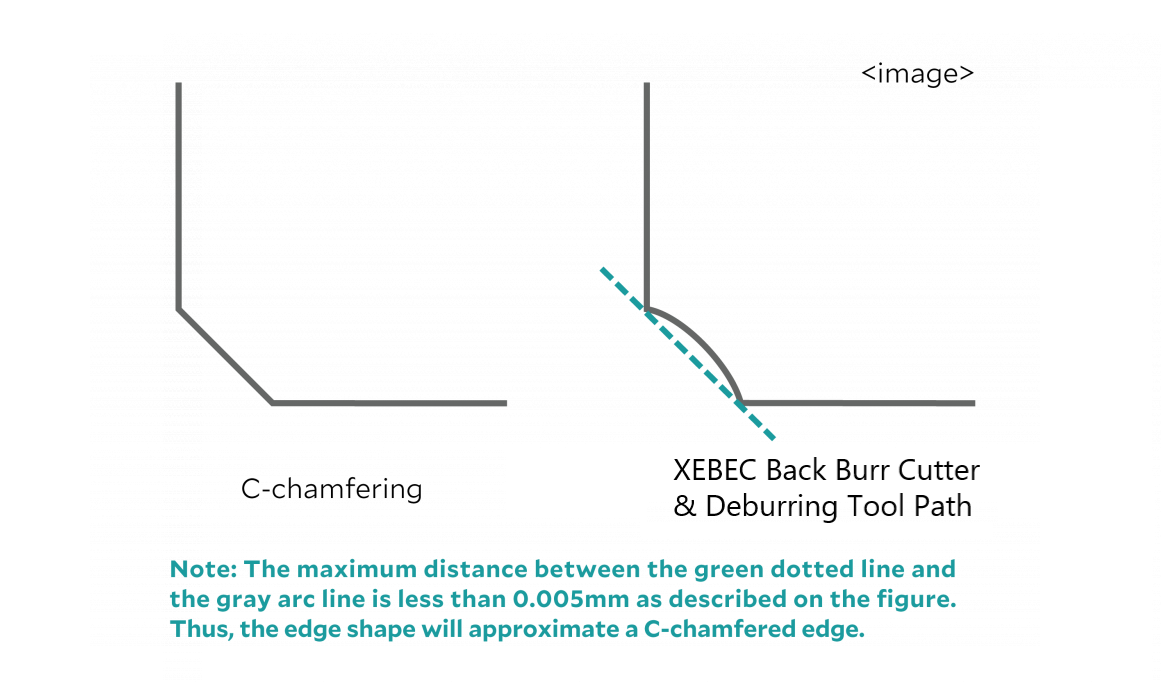

It is not possible to chamfer or round-chamfer the edge.

| Product code | Cutter diameter ΦDc (mm) |

Tool protrusion length (mm) |

Number of blades | Steel, stainless steel, cast iron, heat resistant alloy | Nonferrous metals | ||

| Rotational speed n (min⁻¹) |

Feed rate Vf (mm/min) |

Rotational speed n (min⁻¹) |

Feed rate Vf (mm/min) |

||||

| XC-08-AS-3F | 0.8 | 3Dc | 3 | 20000 | 1080 | 20000 | 1170 |

| XC-13-AS-3F | 1.3 | 3Dc | 3 | 20000 | 1080 | 20000 | 1170 |

| XC-18-AS-3F | 1.8 | 3Dc | 3 | 20000 | 1080 | 20000 | 1170 |

| XC-23-AS-3F | 2.3 | 3Dc | 3 | 15000 | 1350 | 18000 | 1710 |

| XC-28-AS-3F | 2.8 | 3Dc | 3 | 12500 | 1800 | 15000 | 2520 |

| XC-33-AS-3F | 3.3 | 3Dc | 3 | 10600 | 1890 | 12700 | 2250 |

| XC-38-AS-3F | 3.8 | 3Dc | 3 | 9200 | 2160 | 11000 | 2880 |

| XC-48-AS-3F | 4.8 | 3Dc | 3 | 7200 | 1980 | 8500 | 2880 |

| XC-58-AS-3F | 5.8 | 3Dc | 3 | 6000 | 1620 | 7000 | 2160 |

| XC-78-AS-3F | 7.8 | 3Dc | 3 | 4500 | 1620 | 5400 | 1920 |

| XC-98-AS-3F | 9.8 | 3Dc | 3 | 3600 | 1320 | 4300 | 1560 |

| Product code | Cutter diameter ΦDc (mm) |

Tool protrusion length (mm) | Number of blades | Steel, stainless steel, cast iron, heat resistant alloy | Nonferrous metals | ||

| Rotational speed n (min⁻¹) |

Feed rate Vf (mm/min) |

Rotational speed n (min⁻¹) |

Feed rate Vf (mm/min) |

||||

| XC-08-A | 0.8 | 5Dc | 2 | 20000 | 600 | 20000 | 650 |

| XC-13-A | 1.3 | 5Dc | 2 | 20000 | 600 | 20000 | 650 |

| XC-18-A | 1.8 | 5Dc | 2 | 20000 | 600 | 20000 | 650 |

| XC-23-A | 2.3 | 5Dc | 2 | 15000 | 750 | 18000 | 950 |

| XC-28-A | 2.8 | 5Dc | 2 | 12500 | 1000 | 15000 | 1400 |

| XC-33-A | 3.3 | 5Dc | 2 | 10600 | 1050 | 12700 | 1250 |

| XC-38-A | 3.8 | 5Dc | 2 | 9200 | 1200 | 11000 | 1600 |

| XC-48-A | 4.8 | 5Dc | 2 | 7200 | 1100 | 8500 | 1600 |

| XC-58-A | 5.8 | 5Dc | 2 | 6000 | 900 | 7000 | 1200 |

| XC-78-A | 7.8 | 5Dc | 3 | 4500 | 1350 | 5400 | 1600 |

| XC-98-A | 9.8 | 5Dc | 3 | 3600 | 1100 | 4300 | 1300 |

| Product code | Cutter diameter ΦDc (mm) |

Tool protrusion length (mm) |

Number of blades | Steel, stainless steel, cast iron, heat resistant alloy | Nonferrous metals | ||

| Rotational speed n (min⁻¹) |

Feed rate Vf (mm/min) |

Rotational speed n (min⁻¹) |

Feed rate Vf (mm/min) |

||||

| XC-18-B | 1.8 | 10Dc | 2 | 4400 | 220 | 4400 | 220 |

| XC-23-B | 2.3 | 10Dc | 2 | 3500 | 220 | 3500 | 220 |

| XC-28-B | 2.8 | 10Dc | 2 | 2800 | 220 | 2800 | 220 |

| XC-33-B | 3.3 | 10Dc | 2 | 2400 | 190 | 2400 | 190 |

| XC-38-B | 3.8 | 10Dc | 2 | 2000 | 160 | 2000 | 160 |

| XC-48-B | 4.8 | 10Dc | 2 | 1600 | 120 | 1600 | 120 |

| XC-58-B | 5.8 | 10Dc | 2 | 1300 | 100 | 1300 | 100 |

| XC-78-B | 7.8 | 10Dc | 3 | 650 | 70 | 650 | 70 |

| XC-98-B | 9.8 | 10Dc | 3 | 500 | 50 | 500 | 50 |

| Product code | Cutter diameter ΦDc (mm) |

Tool protrusion length (mm) |

Number of blades | Nonferrous metals, resin | |

| Rotational speed n (min⁻¹) |

Feed rate Vf (mm/min) |

||||

| XC-08-A-N | 0.8 | 5Dc | 2 | 20000 | 650 |

| XC-13-A-N | 1.3 | 5Dc | 2 | 20000 | 650 |

| XC-18-A-N | 1.8 | 5Dc | 2 | 20000 | 650 |

| XC-23-A-N | 2.3 | 5Dc | 2 | 18000 | 950 |

| XC-28-A-N | 2.8 | 5Dc | 2 | 15000 | 1400 |

| XC-33-A-N | 3.3 | 5Dc | 2 | 12700 | 1250 |

| XC-38-A-N | 3.8 | 5Dc | 2 | 11000 | 1600 |

| XC-48-A-N | 4.8 | 5Dc | 2 | 8500 | 1600 |

| XC-58-A-N | 5.8 | 5Dc | 2 | 7000 | 1200 |

| XC-78-A-N | 7.8 | 5Dc | 3 | 5400 | 1600 |

| XC-98-A-N | 9.8 | 5Dc | 3 | 4300 | 1300 |

1. Rotational speed and feed rate are a guide for initial machining.

2. To improve the machining parameters, take steps such as adjusting the rotational speed and feed rate, or changing to a Tool Path with a different edge break length.

3. If oscillation or noise occurs or if the rotational speed or feed rate does not satisfy the value in the standard machining parameters table, lower the rotational speed and feed rate by the same proportional amount.

4. Depending on the type of cross hole, care needs to be taken with the setting parameters, so refer to the instruction manual.

5. It is possible to reduce machining shape error by using functions such as advanced preview control.

Secondary burring may occur depending on the state of the intersecting edges. Keep the tool projection length as short as possible, set the feed rate to 50% of the standard parameter, and try starting from a small edge break length.

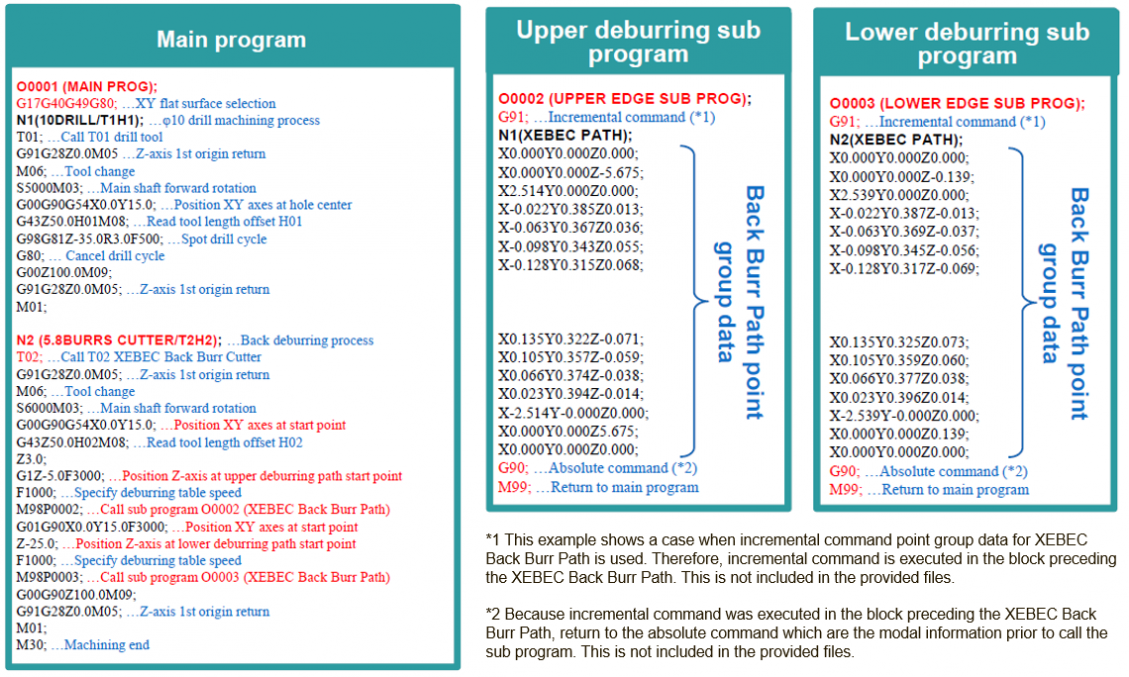

Paths are made by XEBEC Technology and delivered to a customer via email.

Therefore, you only need to install the Tool Path, set a starting point of the Cutter, and set the machining parameters. You do not need to program on your own.

Please refer to the tool guide to see how to set a tool length offset and a starting point.

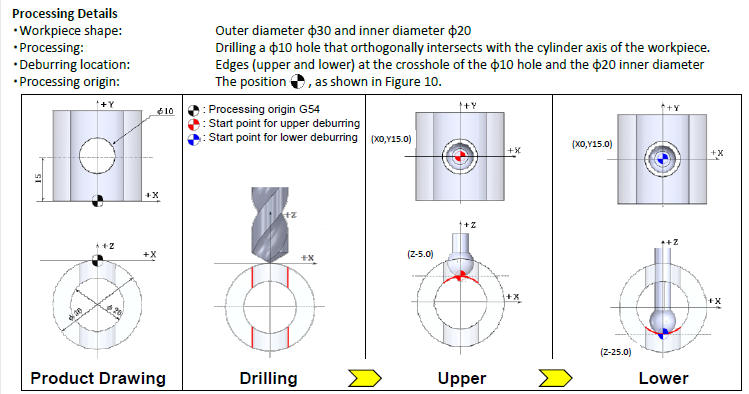

The following explains how to install incremental command point group data for XEBEC Back Burr Cutter & Deburring Tool Path™

(for machining center, B-type hole) on a processing program.

*Control system is set in accordance to FANUC. Please adjust G codes in the program according to your own system.

Perfect for deburring both front and back of a drilled hole.