| Tool | Curved bearing scraper |

|---|---|

| Problem | CNC deburring was not possible due to an off-centered edge. It was not possible for users to make a tool path data. Manual deburring was time-consuming because no scratch was allowed on a certain part of workpiece. |

| Tool | XEBEC Back Burr Cutter & Deburring Tool Path (XC-38-A) |

|---|---|

| Result | Edge quality improved by CNC deburring. Defective products caused by scratches eliminated. |

| Industry | General Machinery |

|---|---|

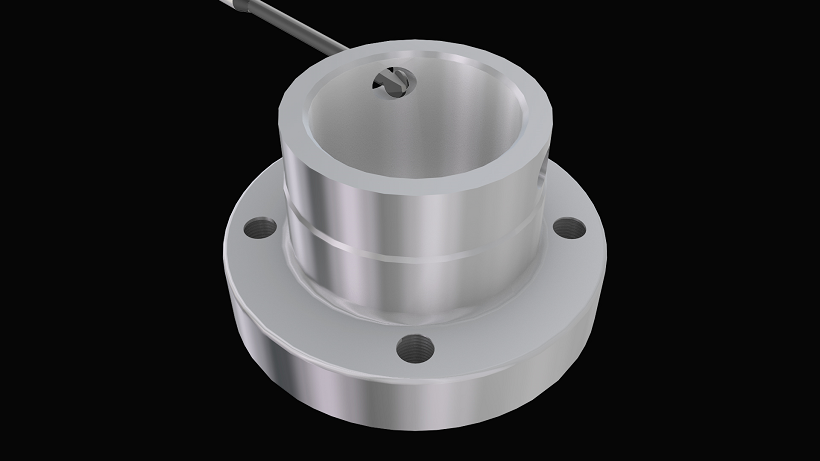

| Part name | Flange (Mounting hole) |

| Material type | Aluminum alloy |

| Cutting process | Drilling |

| Tool | XEBEC Back Burr Cutter & Deburring Tool Path (XC-38-A) |

|---|---|

| Details of processing | Back deburring after drilling |

| Rotational speed (min⁻¹) | 6000 |

| Feed rate (mm/min) | 900 |

| Machining time (sec) | – |

Optimal solution for high-precision deburring of 3D-curved crossholes