| Tool | Twisted brushes and rotary tool |

|---|---|

| Problem | Twisted brush was used with rotary tool. It took man-hour for deburring the inside diameter by manual work. |

| Tool | XEBEC Brush Crosshole (CH-A12-7L) |

|---|---|

| Result | By introduction of automated deburring, workability and quality of inside diameter improved. |

| Industry | Automotive |

|---|---|

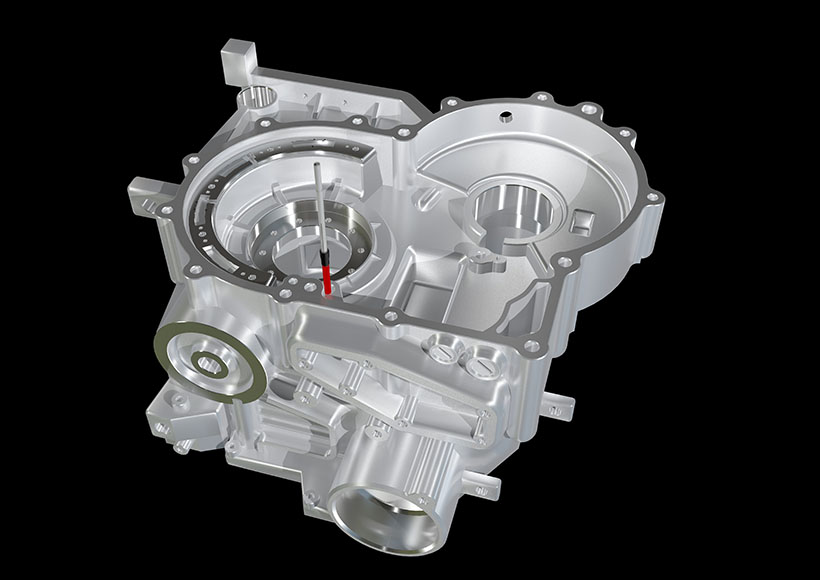

| Part name | Transmission case (Cross hole) |

| Material type | ADC12 |

| Machining process | Drilling |

| Tool | XEBEC Brush Crosshole (CH-A12-7L) |

|---|---|

| Details of processing | Crosshole deburring after drilling process |

| Rotational speed (min⁻¹) | 7,200 |

| Feed rate (mm/min) | 300 |

| Depth of cut (mm) | – |

| Machining time (sec) | – |

Ideal for deburring, polishing, and removing cutter marks on inner diameters and counterbores up to φ20