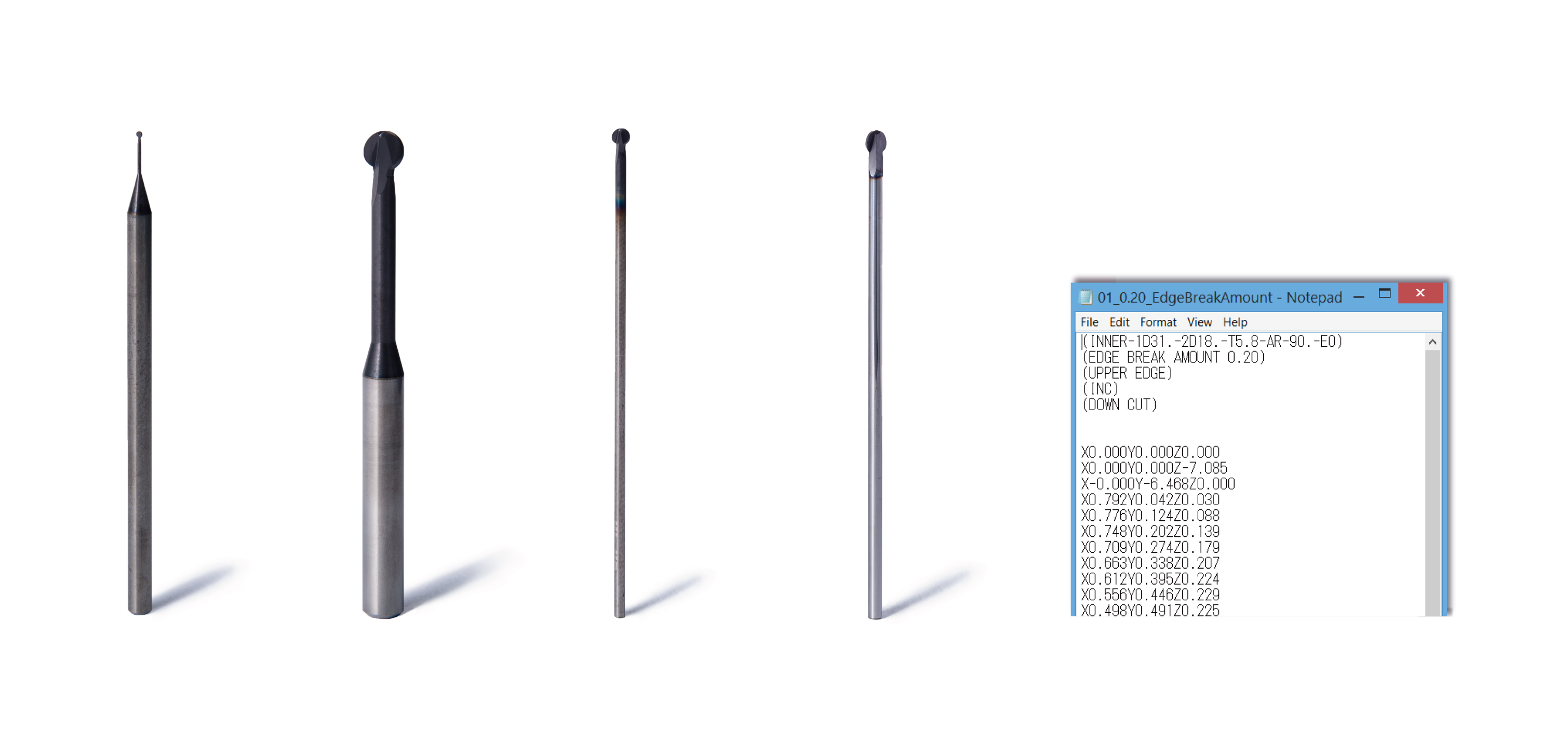

XEBEC Back Burr Cutter & Deburring Tool Path is an innovative CNC crosshole deburring solution, which, in combination with the spherical deburring cutter and the customized NC data set, enables high-precision deburring of 3D-curved cross holes. The NC data set (Path) is created specifically for the customer application, enabling deburring without secondary burr formation. The continuous displacement of the contact point during machining also increases the tool life many times over compared to comparable tool solutions. Numerous successful applications in aerospace, orthopedic medical device, and automotive industries.

Our Tool Path enables high-precision deburring of 3D-curved cross holes, whereas programs made with trigonometric functions may result in millimeters of dimensional variance, depending on the complexity of the cross holes. We create the Tool Path for you, whereas you would need to spend hours to create a program with CAD/CAM. Furthermore, we provide a set of five different deburring amounts (edge break widths), whereas with CAD/CAM, you would need to do everything from the scratch if you need to modify the edge break width.

1. Because the required minimum depth of cut can be controlled precisely.

2. The entire cutting edge is used by changing the point of contact with the work material.

3. Because of uniquely designed cutter focused on materials, coatings and quality.

Strictly speaking, secondary micro burrs may form by cutting the workpiece. However, they remain minuscule until the wear of the Cutter progresses, due to it specially designed features that help to reduce secondary burrs.

This is because the Tool Path (NC data set) enables precise control of the optimal tool position of the Cutter.

Theoretically, it is precise within 0.05mm. However, it may vary due to misalignment of the workpiece or due to chattering.

This is the industry’s fastest back burr deburring solution. High-precision control with the Tool Path (NC data set) enables deburring in one pass and it also allows fast feed rate.

It is possible to remove burrs with root thicknesses that are smaller than the set of five different deburring amounts (edge break widths) we provide. Sets of deburring amounts we provide varies depending on Cutter sizes. For example, we provide fiver different deburring amounts ranging between 0.03-0.07mm with XC-08-A Cutter with diameter of 0.8mm. With XC-58-A Cutter with diameter of 5.8mm, the deburring amounts range between 0.1-0.3mm. It is possible to remove burrs with root thicknesses less than these widths. Please note that XEBEC Back Burr Cutter & Deburring Tool Path may move back and forth over some spots in order to maintain the uniformity of the deburring amount.

It depends on the hardness of the material, but it is possible. However, if the Cutter contacts large burrs, the risk of chipping increases. Therefore, it is recommended to change the milling process to minimize burr formation and to make them as small as possible prior to using this product.

Chamfering is not possible due to the spherical shape of the Cutter. This solution is designed specifically for high-precision deburring of 3D curved cross holes.

The uncoated type of Cutter is applicable to resin and aluminum, and the AlTiCrN-coated type of Cutter is applicable to most materials, including non-ferrous metals and difficult-to-machine materials such as stainless steel and alloys.

It varies depending on the workpiece material, processing parameters (rotational speed, feed rate, deburring amount), chucking (tool diameter, tool projection, chucking method), and burrs (size, shape).

The Back Burr Cutter is made of nano-cemented carbide, and care must be taken when processing materials with similar hardness. The possibility of chipping is likely when processing materials with hardness of about HRC45 and above. If you are concerned about the hardness of the material you need to process, please consider followings.

1.Rather than processing a wide deburring amount in one pass, process it in a few passes in a narrower deburring amount per pass

2.Reduce rotational speed and feed rate to reduce exertions and impacts on the cutter

If you can provide us with detailed information about the material, we will be able to recommend optimal processing parameters. Please contact us at: https://www.xebec-tech.com/en/contact/

Yes, it can, without generating any build-up edges.

Yes, the uncoated type of Cutter can process resins and aluminum.

Please refer to the instruction manual for the standard machining conditions.

It can deburr both. Tool Paths (NC data set) suitable for both types of holes can be made available.

As with other cutting tools, the tool life will be greatly impacted with any intermittent cutting.

If the surface is uneven, it may not be possible to remove completely and in some cases, the Cutter may break.

It depends on how much variances there is. Burrs may remain and the tool may break if the dimensional variance is too great.

It will work if the cumulative error is 0.18mm or less. Allowable cumulative error varies depending on the Cutter diameter.

No. It can be used with any 3-axis machines tools including machining centers and combined lathe. Advanced preview control of the machine tool helps to improve the uniformity of deburred edges.

Reduce the feed rate proportionally.

To determine whether it is possible, we need to receive from you details of the axial configuration (+X +Y +Z directions) and the controlling mode (diameter or radius) for both X and Y axis. Please contact us at: https://www.xebec-tech.com/en/contact/

There is no need to use any specific cutting fluid or coolant. You can use ones that you are already using with other cutting tools (drills, end mills, etc.).

It is made of nano-cemented carbide.

As the Cutter has been designed specifically as a deburring tool, the radial tolerance is not guaranteed.

A:Yes, we can provide drawings as PDF or 3D solid models (STEP files).

Please send your request to: https://www.xebec-tech.com/en/contact/

Yes, it is possible. However, it is highly recommended that you use it with the Tool Path (NC data set) we provide for the optimal performance, edge uniformity, and the tool life.

Yes, it is possible to purchase just one.

We are unable to offer to accommodate any modification request.

Separate Tool Path (NC data set) is needed for the outer and inner edge. So, please fill in the application sheet separately.

We are unable to offer modifications to any Tool Path supplied. However, the Tool Path is offered in text format, allowing you to edit values as needed.

No. We provide the Tool Path under the condition that it will be used with our Cutter, and it cannot be used with any different spherical cutter from any competition.

In creating each Tool Path, the data set for both the upper and lower edges are made available at once. Therefore, a discount is not possible by removing one of them.

Standard Tool Paths (NC data sets) include separate data sets for both the upper and lower edges. Select the one for the edge that you need to deburr.

No, there is no expiry date.

It may be possible.

Please let us know your desired deburring amount when you contact us. We will confirm if it is possible or not.

Only NC data set (XYZ axis coordinates) is included. Please add G codes, M codes and O (zero) numbers preceding program numbers, as needed. Also note that the Tool Path does not include the feed rate command (F code).

It is offered in a text format (.txt). It can be edited with any text software.

it varies depending on the features, complexity, and sizes of the workpiece. For example, the Tool Path would be about 2KB, consisting of abort 80 rows of coordinates when the primary bore diameter is 20mm and the cutter insertion hole diameter is 10mm.

Generally, it is less than 5KB.

It is at the same position as the start point, away from any surface.

We can deliver it to you within 3 business days after you place your order.

Yes, as long as it is used temporarily for a specific purpose of test cut or for the setup of the machine. However, we ask you to be responsible that it be not used for any purpose other than its intended purpose.

There is no upper limit of rotational speed for the cutter itself, but please make sure that the speed does not exceed the maximum for the tool holder. However, make sure that the tool runout is 0.01mm or less for the Straight Type Cutters.

No. The Cutter will not be able to contact workpiece edges if re-sharpened, because the Tool Path (NC data set) we provide are created precisely based on the initial Cutter diameter.

No, it is not possible. The Tool Path works only with the initial cutter diameter.

It varies depending on various factors including the material of the workpiece, the positional deviation of the holes, the rigidity of fixture, burr sizes.

However, in general, the total cutting distance that the Cutter is capable of is about 100m.

If the cutting distance is shorter than 100m, it may be possible to improve it in some cases.

If you are using a path program that you created, it may be possible to extend the tool life by switching to XEBEC Tool Path.

In one case, the tool life was extended to 4 times longer by changing to our Path program.

It can be possible to extend the tool life by using the short type of Cutter with 3 blades if the workpiece does not interfere the Cutter.

For the best possible solution, please contact us and let us know the details such as the workpiece description and processing conditions.