| Tool | Sandpaper |

|---|---|

| Problem | It was necessary to use multiple types of abrasive papers and it took long time for polishing. Additionally, manual deburring process caused unstable finish quality. |

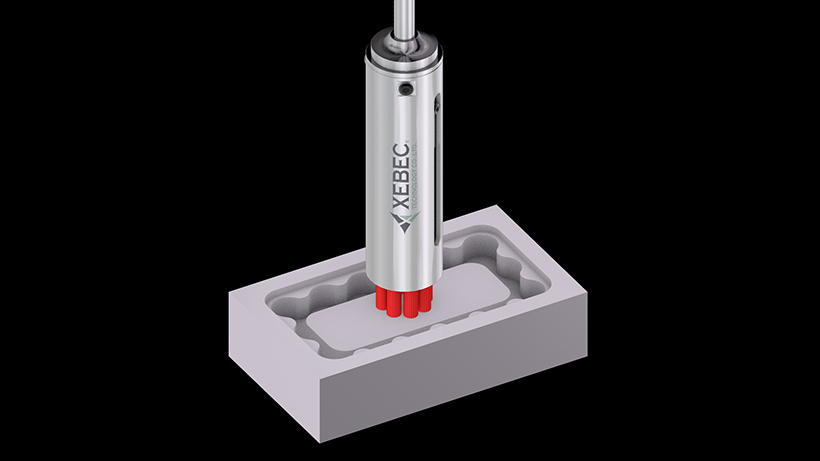

| Tool | XEBEC Brush Surface (A11-CB25M) |

|---|---|

| Result | Polishing in a shorter cycle time with stable quality realized. |

| Industry | Mold |

|---|---|

| Part name | Vacuum forming |

| Material type | Aluminum alloy |

| Machining process | End mill processing |

| Tool | XEBEC Brush Surface (A11-CB25M) |

|---|---|

| Details of processing | Removal of cutter marks and polishing after end milling process |

| Rotational speed (min⁻¹) | 3,600 |

| Feed rate (mm/min) | 4,000 |

| Depth of cut (mm) | 0.3 |

| Machining time (sec) | – |