| Tool | Sandpaper |

|---|---|

| Problem | Low production rate due to unstable surface roughness. Short tool life of sandpaper caused a cost problem. |

| Tool | XEBEC Brush for Surface (A21-CB25M)/ |

|---|---|

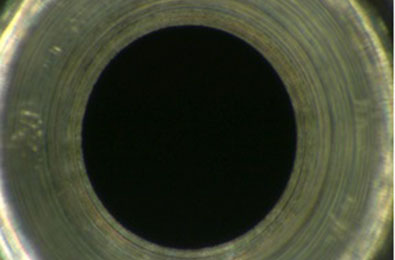

| Result | Required surface roughness realized in shorter cycle time. Reduction of labor costs corresponding to 20 hours of manual deburring work with sandpaper has been achieved. |

| Industry | Automotive |

|---|---|

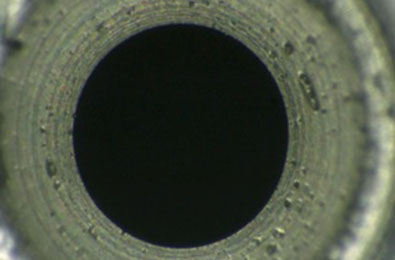

| Part name | Common rail |

| Material type | S48C |

| Machining process | Grinding |

| Tool | XEBEC Brush for Surface (A21-CB25M)/ |

|---|---|

| Details of processing | Deburring the seal surface after grinding process |

| Rotational speed (min⁻¹) | 3,000 |

| Feed rate (mm/min) | – |

| Depth of cut (mm) | 4 |

| Machining time (sec) | – |

Predetermined Brush length is automatically projected and assists unmanned operation. Effective to eliminate human error, maintain optimal machining conditions and consistent machining quality.