| Tool | Cutter, sandpaper |

|---|---|

| Problem | Manual deburring caused unstable quality and high labor cost. |

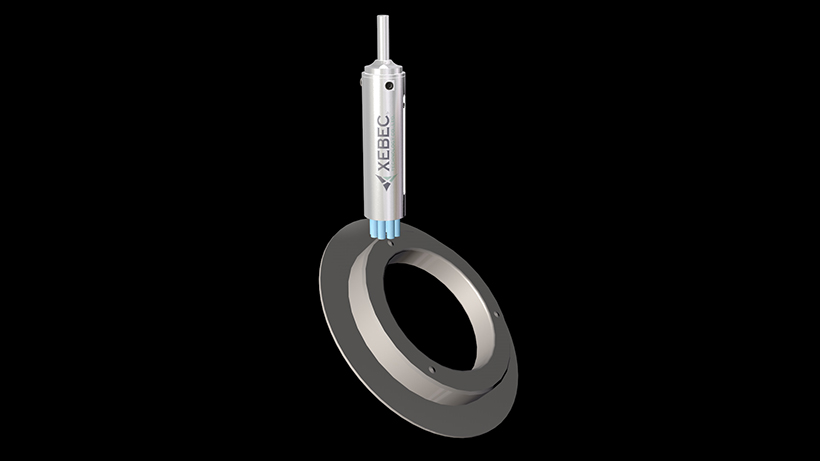

| Tool | XEBEC Brush for Surface (A31-CB25M) |

|---|---|

| Result | Fully automated deburring enabled stable quality and shorter processing time. Also the efficiency of processing improved by changing the burr direction by review of pre-process. |

| Industry | Automotive |

|---|---|

| Part name | Yoke |

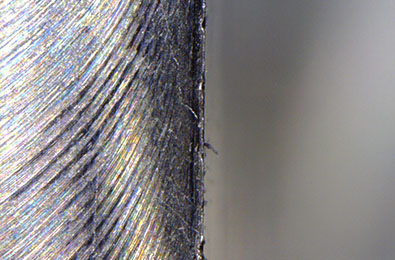

| Material type | Stainless steel |

| Machining process | Chamfering |

| Tool | XEBEC Brush for Surface (A31-CB25M) |

|---|---|

| Details of processing | Deburring the section after chamfering process |

| Rotational speed (min⁻¹) | 3,000 |

| Feed rate (mm/min) | – |

| Depth of cut (mm) | 1 |

| Machining time (sec) | – |