| Tool | Rubber wheel, carbide rotary bar on the rotating tool |

|---|---|

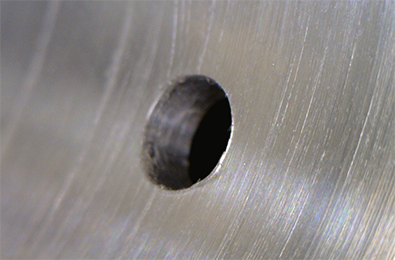

| Problem | The shape of edge was damaged and secondary burrs generated by deburring. |

| Tool | XEBEC Stone Flexible Shaft Type (CH-PM-5B) |

|---|---|

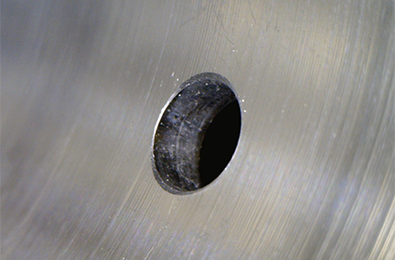

| Result | Allows the tool to contact with bending the shaft softly (displacement of bending = 0.5mm approximately). |

| Industry | General Machinery |

|---|---|

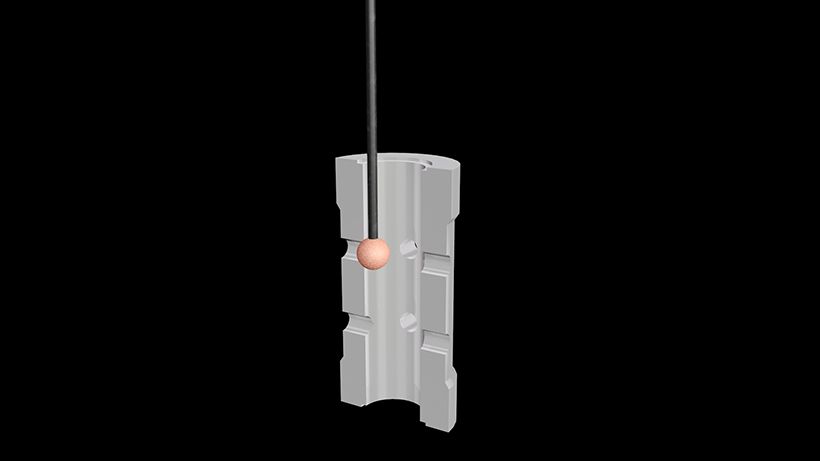

| Part name | Hydraulic valve (Cross hole) |

| Material type | Steel-based |

| Machining process | Drilling |

| Tool | XEBEC Stone Flexible Shaft Type (CH-PM-5R-C01) |

|---|---|

| Details of processing | Cross hole (blind hole) deburring after drilling process |

| Rotational speed (min⁻¹) | 5000-8000 |

| Feed rate (mm/min) | – |

| Depth of cut (mm) | 0.5 |

| Machining time (sec) | – |

Ideal for deburring and polishing front and back of cross holes, grooves and areas that are deep inside the workpiece.

The spring steel flexible shaft absorbs vibrations which makes soft contact with the surface possible.