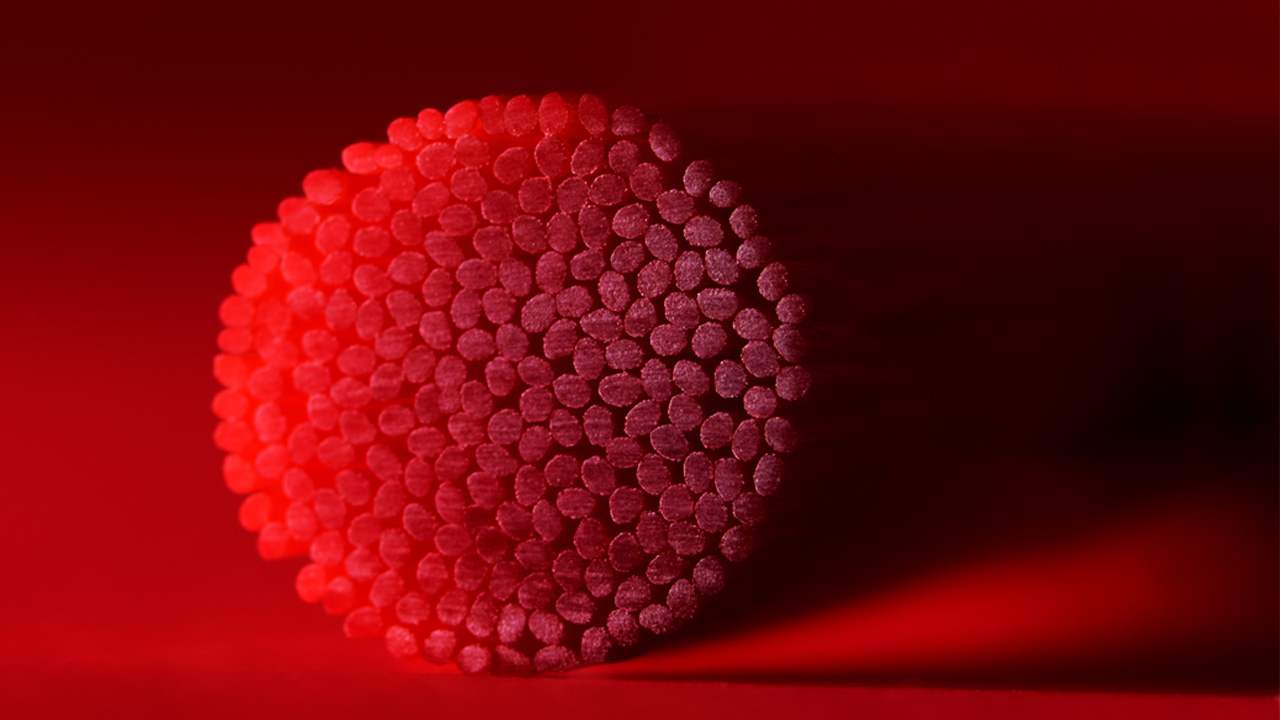

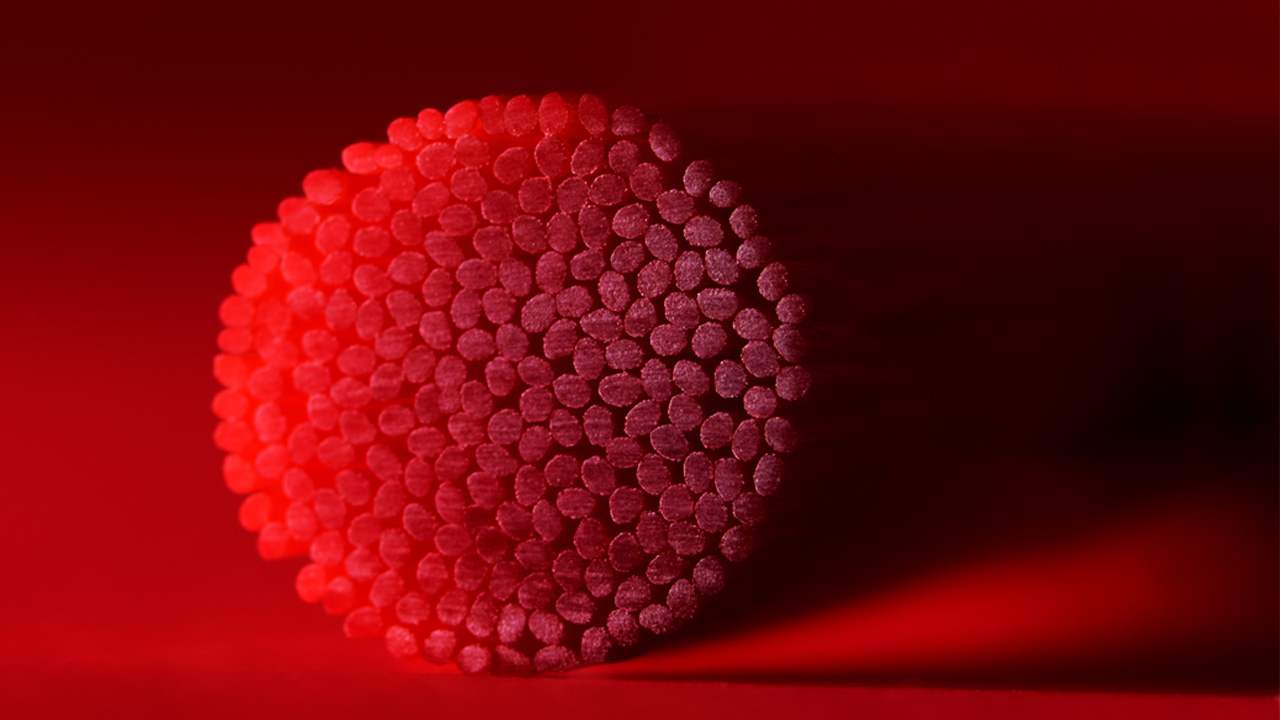

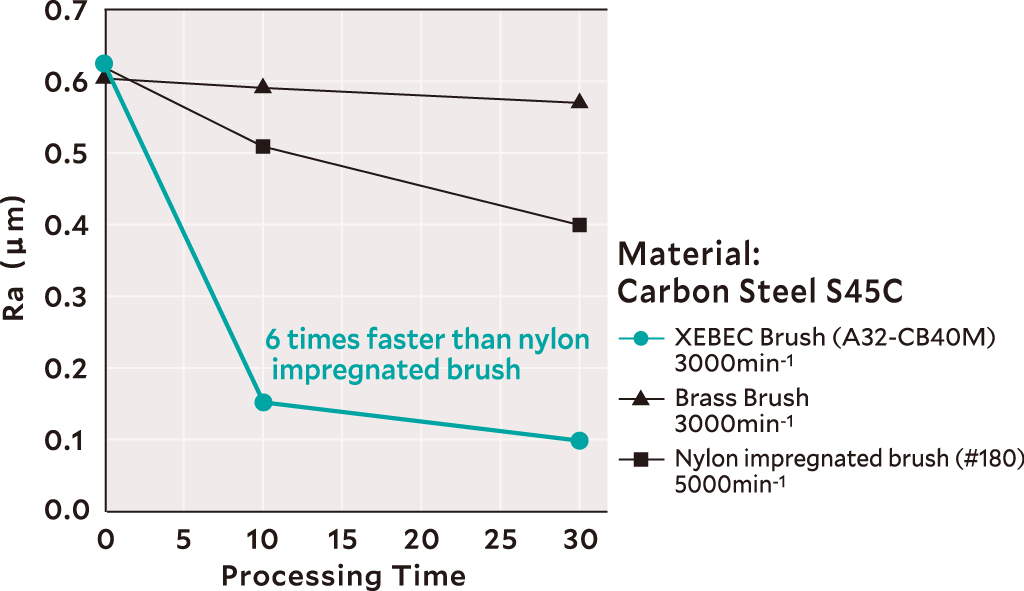

XEBEC Brush uses unique abrasive ceramic fiber material instead of abrasive grain.

Each bristle consists of 1,000 ceramic fibers that work as cutting edges.

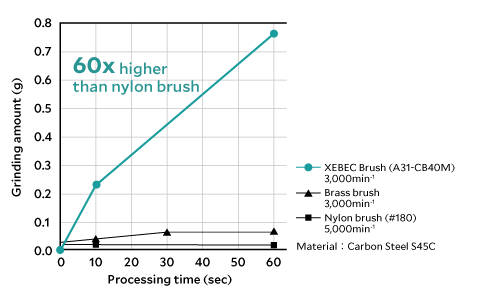

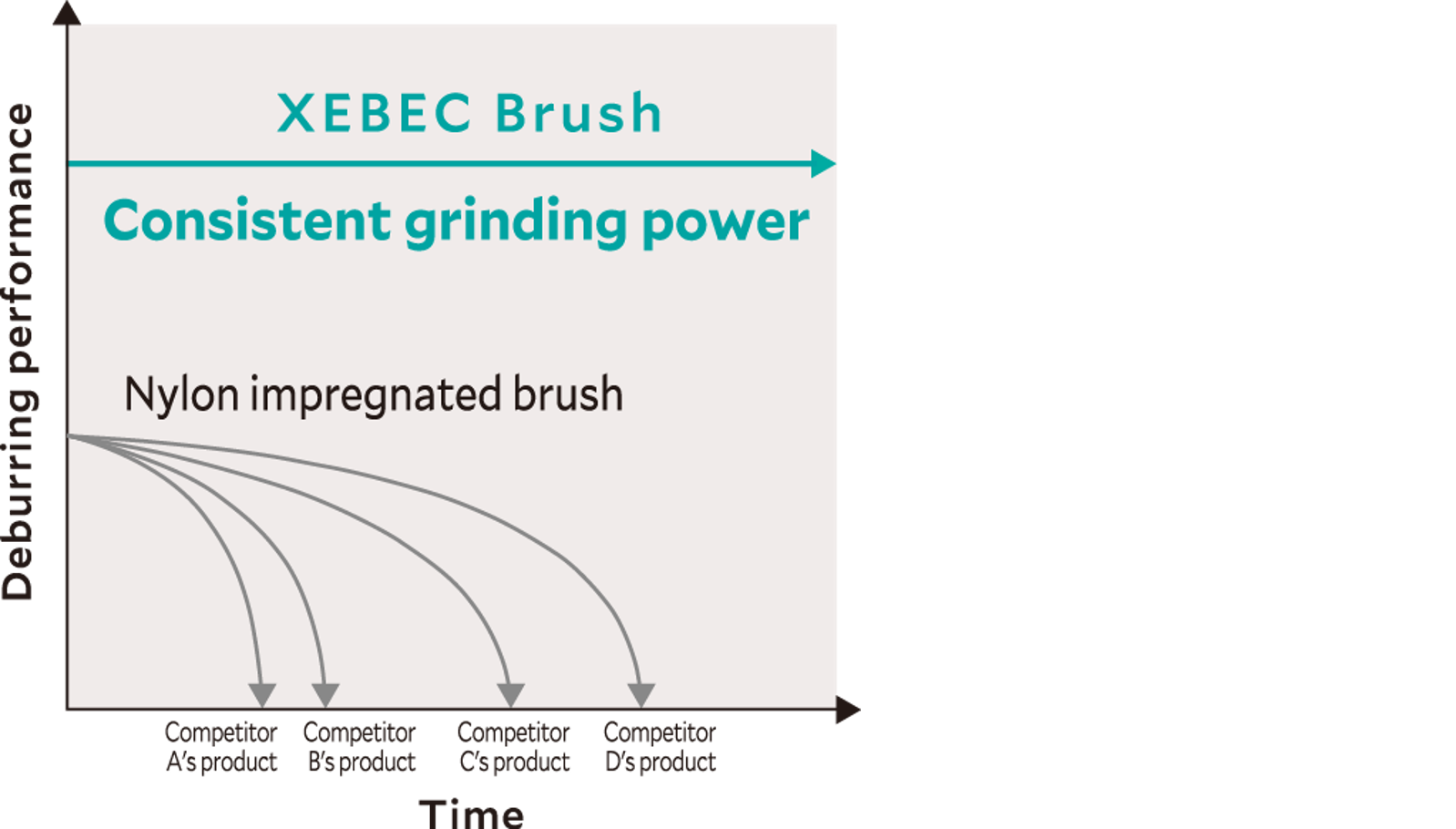

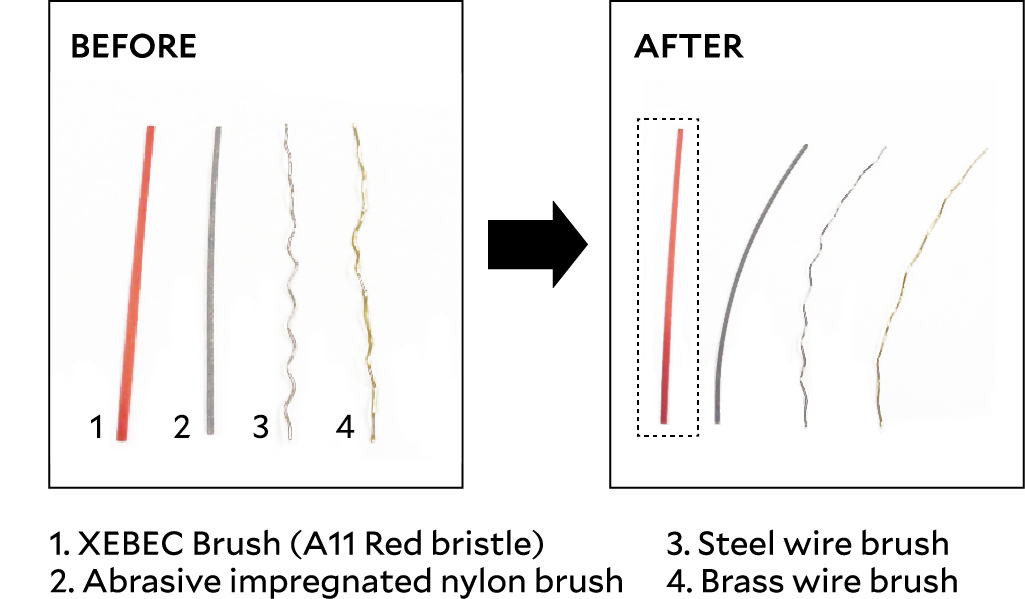

Overwhelming grinding power, Consistent cutting performance, No deformation.

Enables CNC deburring immediately after milling and machining operations inside the same machine tool.

Ideal for polishing and removing cutter marks on inner diameters and sealing surface

Ideal for deburring, cutter mark removal and surface polishing with a width of 100mm or more

Ideal for deburring and polishing inner diameters, side walls, and thread outside diameters

Ideal for deburring, polishing, and removing cutter marks on inner diameters and counterbores up to φ20

Ideal for deburring, polishing, and removing cutter marks on inner diameters and counterbores between φ20 and φ35

Ideal for deburring, polishing, and removing cutter marks on inner diameters and counterbores exceeding 150mm in depth

Automatically adjusts the Brush projection length with the built-in gear mechanism.

Helps prevent human errors and achieve consistent machining performance.

The built-in spring helps to maintain stable load, which enables consistent performance, while reducing the need to adjust the Brush projection length frequently.

Compact tool holder whose length under the gauge line is 23.5mm (including bush flange thickness 1.5mm).

Optimal when available space is limited.