How to Use (Regular Type)

Brush in Use

How to Use

Basics of Using the Brush

The Brush can only remove burrs and finish surfaces at its tip. The recommended depth of cut is 0.5 mm to 1.0 mm, with a maximum depth of 1.5 mm.

Appropriate Depth of Cut and Tool Load

Using the Brush with excessive depth of cut or tool load may prevent optimal results and cause significant tool wear, shortening tool life and breaking bristles.

Adjustment of Rotational Speed and Depth of Cut

- If burrs remain, increase the rotational speed and the depth of cut. If edge rounding is excessive, decrease the rotational speed and the depth of cut.

- As the length of the bristle becomes shorter as a result of tool wear, the bristle stiffness and grinding power increase, and conformability decreases. Adjust the grinding power and conformability by reducing the rotational speed and the depth of cut.

Brush Rotational Direction and Deburring

The rotational direction of the Brush significantly affects deburring performance.

Vertical burrs:

For vertical burrs generated by drilling and end milling, deburring capability is not affected significantly by rotational direction.

Horizontal burrs:

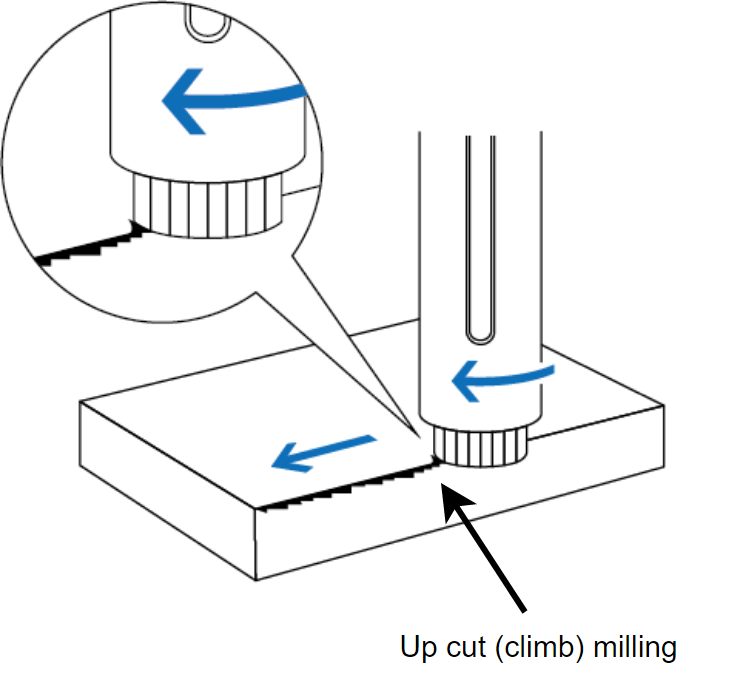

For horizontal burrs generated by face milling, the Brush should be applied in a way that it pushes burrs upward and up cut (climb) milling ensures this. On the other hand, down cut (conventional) milling may only push or bend burrs down without removing them.

Up / Down Cut Milling

Dry and Wet Machining

The Brush can be used with or without cutting coolant (oil-based and water-soluble), and you can use the same coolant as the one you are using for other cutting processes.

Using coolant may improve surface roughness and extend tool life.

Tool Holder

Use a collet chuck or a milling chuck as the tool holder.

Do not use the following types of tool holders:

- Shrink-fit holder:

The sleeve shank is made of stainless steel, not solid carbide, and this may prevent its removal from a shrink-fit holder. - Hydro chuck:

The sleeve shank may slip off from a hydro chuck since the shank diameter of the sleeve is made only to h7 dimensional tolerance preventing the chuck from holding it properly. - Side lock holder:

The sleeve shank is made of stainless steel and it may deform when it is fixed in a side lock holder with a screw, and this may prevent its removal from the holder.