Machining Parameters (Regular Type)

Different starting machining parameters are recommended for deburring, cutter mark removal and polishing.

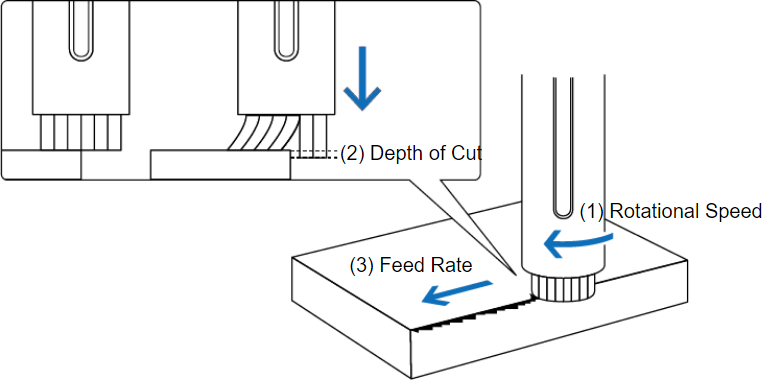

Machining parameters include (1) rotational speed (2) depth of cut and (3) feed rate.

Furthermore, different Brush protruding length is recommended for each Brush sizeand different rotational direction is recommended depending on the burr direction.

Starting Machining Parameters

Deburring

Product code |

(1) Rotational speed (min-1) |

(2) Depth of cut (mm) |

(3) Feed rate (mm/min) |

Brush protruding length (mm) |

|||

|---|---|---|---|---|---|---|---|

Recommended |

Maximum |

Vertical burrs |

Horizontal burrs |

Burr thickness 0.05 mm |

Burr thickness 0.1 mm |

Maximum rotational speed (min-1) |

|

A13-CB06M |

8000 |

10000 |

0.5 |

0.5 |

4000 |

2500 |

10 |

A32-CB06M |

8000 |

10000 |

0.3 |

0.3 |

4000 |

2500 |

10 |

A13-CB15M |

4800 |

6000 |

1 |

1 |

4000 |

2500 |

10 |

A11-CB15M |

4800 |

6000 |

0.5 |

1 |

4000 |

2500 |

10 |

A11-CB25M |

4000 |

5000 |

0.5 |

1 |

4000 |

2500 |

15 |

A11-CB40M |

2400 |

3000 |

0.5 |

1 |

4000 |

2500 |

15 |

A11-CB60M |

1600 |

2000 |

0.5 |

1 |

4000 |

2500 |

15 |

A11-CB100M |

960 |

1200 |

0.5 |

1 |

4000 |

2500 |

15 |

Cutter Mark Removal, Polishing

Product code |

(1) Rotational speed (min-1) |

(2) Depth of cut (mm) |

(3) Feed rate (mm/min) |

Brush protruding length (mm) |

|---|---|---|---|---|

A13-CB06M |

10000 |

0.3 |

250 |

10 |

A32-CB06M |

10000 |

0.3 |

250 |

10 |

A13-CB15M |

6000 |

0.5 |

450 |

10 |

A11-CB15M |

6000 |

0.5 |

450 |

10 |

A11-CB25M |

5000 |

0.5 |

700 |

10 |

A11-CB40M |

3000 |

0.5 |

800 |

10 |

A11-CB60M |

2000 |

0.5 |

850 |

10 |

A11-CB100M |

1200 |

0.5 |

850 |

10 |

|

|