| Tool | Round bar grindstone |

|---|---|

| Problem | Manual use of rod grindstone. It was necessary to form the tip of the grindstone to polish the tapered portion. Manual processing resulted in unstable polishing quality. |

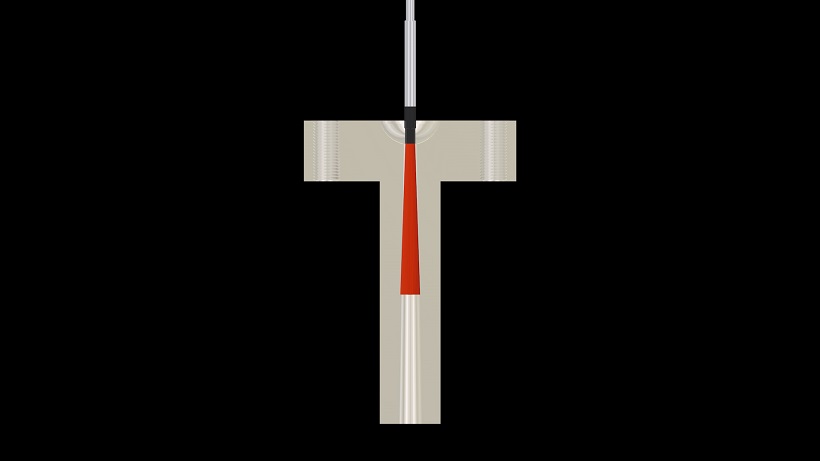

| Tool | XEBEC Brush Crosshole (CH-A12-3M) |

|---|---|

| Results | Work efficiency improved because the shape of a brush fits to the tapered portion of a workpiece. Enables to remove cutter marks in a shorter time. |

| Industry | Mold |

|---|---|

| Part name | Mold (Sprue hole) |

| Material type | SKD2 |

| Machining process | Others |

| Tool | XEBEC Brush Crosshole (CH-A12-3M) |

|---|---|

| Details of processing | Removal of cutter marks and polishing after electrical discharge machining |

| Spindle speed (min⁻¹) | 10,000 |

| Table feed (mm/min) | – |

| Depth of cut (mm) | – |

| Machining time (sec) | – |

Ideal for deburring, polishing and cutter mark removal on inner diameter and counterbored part